- Harbors and port terminals >

- Cargo handling >

- Twin-lift type spreader

Twin-lift type spreaders

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... system is of box type design and driven by hydraulic cylinders. CONTROL AND PROTECTION SYSTEM For safety and reliability, the control voltage on the spreader is always converted to 24V DC. Electrical ...

... all-electric twin-lift separating spreader is designed to support terminals in achieving their environmental goals without sacrificing productivity or efficiency. The Bromma all-electric ...

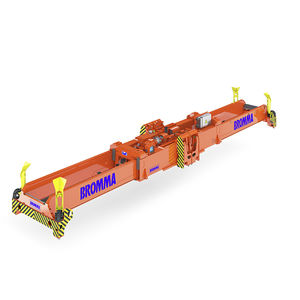

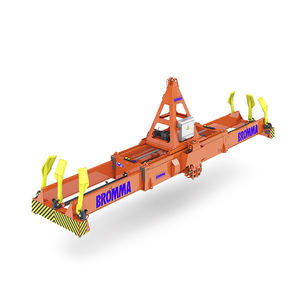

BROMMA

... Bromma Tandem E³ spreader offers great capacity and flexibility. Low spreader weight is combined with the ability to lift different combinations of 40 or 45 foot containers or single ...

BROMMA

... a high percentage of 40´containers will gain an immediate boost to its lift cycle productivity by changing from single-lift 40´ container handling to a Tandem Fixed-Length spreader. In ...

BROMMA

... productivity per lift cycle with no potential “downside” in terms of downtime created by change-outs. This spreader is also based on proven Bromma spreader design, as it uses the Bromma ...

BROMMA

... to be loaded/unloaded in single lift mode. The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European high quality steel, which ensures a ...

BROMMA

... ’s most versatile and flexible spreaders, the twin-lift function makes it possible to lift a broad variety of container sizes and combinations. The spreader ...

BROMMA

... good backup spreaders if the usual spreader is taken out of operation. The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European ...

BROMMA

... backup spreaders if the usual spreader is taken out of operation. The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European ...

BROMMA

... hydraulic separating twin-lift spreader for use in ship-to-shore cranes. Bromma STS45 spreader is the industry standard for ship-to-shore container handling and it is ...

BROMMA

... from each lift, Bromma offers a telescoping twin-lift mobile harbor crane spreader, EH170U, capable of handling two 20´containers. Description Possible container ...

BROMMA

The 2900 series is a telescopic twin lift ship to shore container spreader, which is electro-hydraulically operated and controlled from the crane's cabin. The spreader ...

RAM Spreaders

... telescopic twin lift yard container spreader, which is powered all electrically and controlled from the crane's cabin. The spreader can be designed to interface with ...

RAM Spreaders

The 2900 series is a telescopic twin lift spreader for Rubber Tire Gantry Crane or Rail Mounted Gantry Crane operations. It is hydraullically operated and controlled from the crane's ...

RAM Spreaders

... telescopic twin lift container spreader for mobile harbour cranes and jib cranes, powered hydraulically and controlled from the crane's cabin. The spreader is fitted ...

RAM Spreaders

... to fill port automation's last challenge 'twistlock handling'. The machine is fully automated, removing and replacing all types of ISO twistlocks in ship to shore quayside or drive-through operations. The automated ...

RAM Spreaders

Your suggestions for improvement:

A twin-lift spreader is a special kind of spreader. While many spreaders feature variable arm length, this type can lift two 20-foot containers at the same time.

ApplicationsThese spreaders are capable of lifting containers of different sizes. Their ability to handle two 20-foot containers at the same time reduces cargo-handling time. Commonly used with gantry cranes, they also can be installed on trucks or other types of crane.

TechnologiesMost such spreaders are telescopic, enabling them to lift different size containers.

How to chooseAs with any telescopic spreader, choice criteria include weight, telescopic range, consumption, arm speed and torque. Of course, the determining factor will be the need to handle two containers simultaneously.

- Size adaptability

- Reduction in cargo-handling time

- Maintenance

the best suppliers

Subscribe to our newsletter

Receive regular updates on this section.

Please refer to our Privacy Policy for details on how NauticExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining