- Ship and boat building

- Materials and paints

- Foam core material

- 3D|CORE GmbH & Co. KG

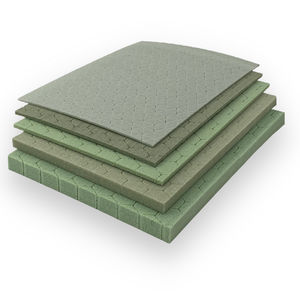

Foam core material 3D|CORE™ XPShoneycombhigh-performance

Add to favorites

Compare this product

Characteristics

- Type

- foam, honeycomb

- Properties

- high-performance

Description

The 3D|CORE™ XPS foam core is a high-performance polystyrene foam that is suitable for ultra-light construction applications. The integrated honeycomb structure creates more flexibility and simplifies handling in production. With the various 3D|CORE™ structures, the technical properties of the foam can be improved to a high-performance core with low weight!

Properties of 3D|CORE™ XPS:

- Available density: 45 kg/m³

- Closed cell foam core (no water absorption, no re-expansion, no outgassing)

- Durability - no rotting

- Very lightweight foam core

- Easy application with epoxy resin systems

- Homogeneous bonding of all components

- Excellent surface adhesion (bond between surface and core)

- Uniform material properties

- Good thermal insulation

- Integrated flow aid

- Low resin absorption

- Can be used with all known epoxy and PU resin systems (Not applicable with styrene)

Areas of application for 3D|CORE™ XPS in the marine industry:

- Components: hull, deck, interior, housings

- For: sailing yacht, motor yacht, catamaran, passenger ferry, specialised vessel, leisure sector (canoe, kayak, jet ski, surf and kiteboard)

Suitable processes:

- Hand lay-up

- Vacuum Infusion

- Vacuum Assisted Light-RTM

- Bonding

Catalogs

TDS 3D|CORE™ XPS

2 Pages

Related Searches

- Sandwich panel

- Ship partition wall sandwich panel

- Wood sandwich panel

- Ship fitting sandwich panel

- Core material

- Honeycomb sandwich panel

- Metal sandwich panel

- Foam sandwich panel

- Aluminum sandwich panel

- Interior floor sandwich panel

- Ship ceiling sandwich panel

- Yacht sandwich panel

- Honeycomb core material

- Composite sandwich panel

- Fiberglass sandwich panel

- Ship floor sandwich panel

- Foam core material

- Fire protection sandwich panel

- PET foam sandwich panel

- Carbon sandwich panel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.