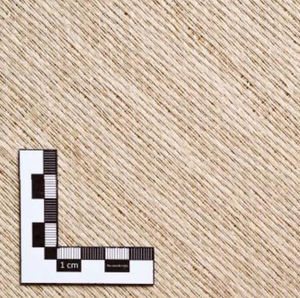

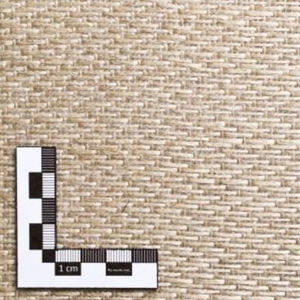

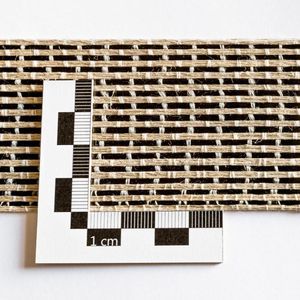

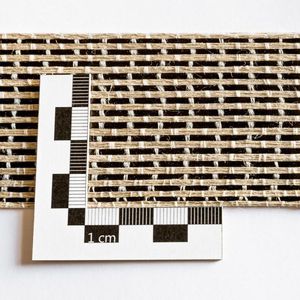

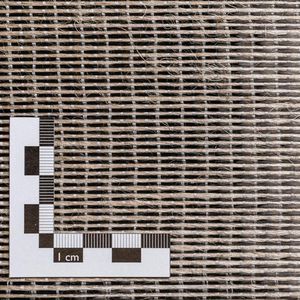

Flax fiber composite fabric 5051braid

Add to favorites

Compare this product

Characteristics

- Fiber

- flax fiber

- Type

- braid

Description

Product description

Flax fibre braid, suitable for manufacturing fibre reinforced

composite tubes with high performance and low

environmental impact.

Performance advantage

Considering that glass fibers have a density of

2600 kg/m3 and a tensile modulus of 70 GPa, the

flax ampliTex® braid can replace a 50.8 g/m glass

fiber braid

Processing guidelines

• Great compatibility with epoxy and polyester

• Near zero CTE, hence good processing compatibility with carbon fibres

• Compatible with infusion based processes (vacuum infusion, RTM), wet layup, bladder inflation

moulding (BIM) and compression moulding

• Flax fibres always contain some humidity at ambient conditions. Some resins (especially

polyesters) are sensitive to moisture and may badly polymerize or create bubbles. In that case, dry

the fabrics before use (110°C for 15 minutes)

• Fibre weight fraction of 50% can be reached with process pressure > 5 bars. However, the fibres

absorb a lot of resin when hand-laminating the fabric and it tends to look “dry” (unless too much

resin is used) before pressure is applied. We recommend controlling the amount of adhesive used

for laminating and impregnating it with 50 to 60% resin in weight. Excess resin comes out while

pressing the fabric.

Catalogs

ampliTex® 5051

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.