- Maritime equipment

- Water, Waste, Emissions and discharge reduction

- Ship liquid cooler

- Blokland Cooling & Propulsion

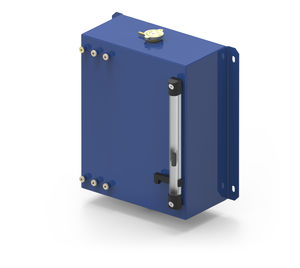

Ship liquid cooler ICAF

Add to favorites

Compare this product

Characteristics

- Options

- for ships

Description

Using Blokland boxcoolers in the design of efficient cooling system, has been done during many years for different types and sizes of ime vessels and installations. Installed in the primary cooling circuit, boxcoolers obviate the need for raw water pumps, filters and piping systems and prevent the corrosion issues related to them. Over the years different types of workboats, cargo vessels, fishing boats, ferries and dredgers have been using these coolers for main engines, generators and auxiliary systems. Nowadays boxcoolers are not only used in modern fuel-saving and green fuel propulsion solutions, but are also part of the fuel saving measures.

Boxcooler applications

Boxcoolers can operate in fresh- and brackish water, seawater and in special environments. A boxcooler will be supplied as a package, complete with a steel or aluminium welding frame, avoiding the need for drilling and tapping. Boxcoolers can be supplied in many sizes and shapes, with cooling surfaces from just over 0,5 m² to more than 150 m². The depth of a boxcooler can be adjusted for shallow draft applications, while the shape can be designed to follow the curvature of a ships hull.

Boxcoolers with certificate

When required, the boxcoolers will be supplied with a test- and witness certificate from a classification societies of choice. Blokland has extensive experience with many class societies, such as: ABS, BV, DNV-GL, KR, LRS,NKK, RINA, RMRS, RRR etc.

Boxcoolers and Marine Growth

Boxcoolers are in direct contact with the water the ship sails in. The biodiversity in coastal regions and estuarine conditions can be responsible for the growth of biological fouling, also on the boxcoolers.

Catalogs

No catalogs are available for this product.

See all of Blokland Cooling & Propulsion‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.