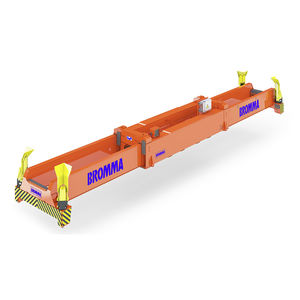

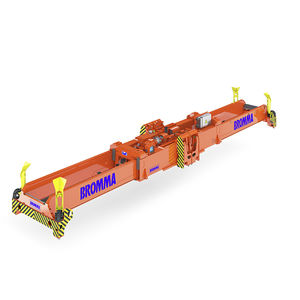

Container spreader STR40Etwin-lift typeelectric

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for containers

- Type

- twin-lift type, electric

Description

Possible container combinations: 20´, 30´, 40´, (45´), 2×20´

STR40E/STR45E are good alternatives for the smaller and less busy terminals but also good backup spreaders if the usual spreader is taken out of operation.

The spreader is designed in accordance with EN13001. As all Bromma spreaders it is made from European high quality steel, which ensures a light and robust design. The spreader has a user friendly design and all components are easily accessible for inspection and maintenance. All-electric spreaders from Bromma reduce consumables, lessen CO2 emissions through lower crane power consumption, protect water through the elimination of oil leaks, enhance worker safety, and lower spreader noise. In addition they are strong and light, substantially lighter than the spreaders they replace.

All-electric

These are all-electric spreaders and they will help ports make additional strides toward “greener” operations. As all Bromma all-electric spreaders they have clear operating advantages:

Light

Quiet

More energy efficient – as much as 85% lower spreader energy consumption

Fast, easy and less costly than many other spreaders to service

Low service materials cost (for oil and filters)

Reduced scheduled service time, thereby increased spreader uptime

Reduced un-scheduled service time, due to the elimination of many of the “nuisance” downtime events that occur due to spreader hydraulics (bad hose connections, .)

Eliminate the clean-up costs associated with oil spills

Specifications

Lifting capacity (SWL)

One container 51 metric tons evenly loaded

One container 51 metric tons ± 10% eccentric load

Twin-lift of two 20’ containers 2 x 32.5 metric tons evenly loaded

Catalogs

Ship to shore spreaders

24 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.