- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

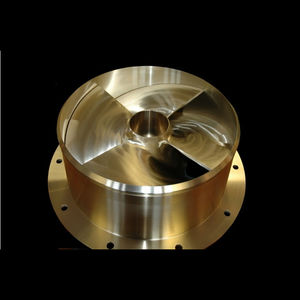

Boat propeller shaft bracket

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Options

- for boats

Description

Our shaft brackets are designed bespoke to achieve optimum performance in line with every vessel’s individual requirements. A low drag areafoil section is applied to all struts ensuring the highest efficiency and performance and lowest vibration level is delivered every time. Our shaft brackets range from a bore size of 25mm to 180mm diameter up to a cast weight of 600kg.

A 3D model is produced for all component drawings and is used for CFD and FEA to provided optimised hydrodynamic geometries and strength analysis. The developed 3D model can be issued to the customer allowing them to import the file into the 3D hull geometry. This ensures precise and accurate fitting is achieved before any tooling manufacture begins. The 3D model is then used to produce tooling as an exact replica of the finalised design. It is then ready for the casting procedure.

Catalogs

No catalogs are available for this product.

See all of CJR Propulsion‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Propeller

- Fixed-pitch propeller

- Boat propeller

- Propeller shaft propeller

- 4-blade propeller

- 3-blade propeller

- Bronze propeller

- 5-blade propeller

- Rudder blade

- Mechanical seal

- Propeller shaft mechanical seal

- Shaft

- Boat shaft

- Boat propeller shaft bracket

- Propeller shaft bracket

- Stern tube

- 6-blade propeller

- Boat stern tube

- Motor boat rudder blade

- Cutlass bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.