- Equipment

- Propulsion, Engine controls

- Boat shaft

- CJR Propulsion

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

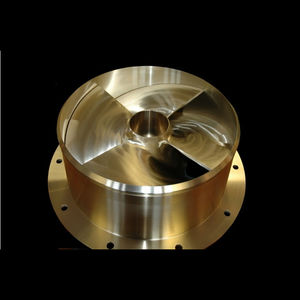

Boat shaft

Add to favorites

Compare this product

Characteristics

- Application domain

- for boat

Description

Shaft design starts with designing entire shaftline incorporating all the components from the propeller to the gearbox and including the bearings to make the system safe, vibration free and efficient in operation. Shaft alignment calculation and lateral vibration analysis can be of a great help to that as it allows in-depth analysis of the shaftline. This assists with the overall design, position and offsets of bearings to be optimised to reduce vibration, especially at certain critical engine speeds.

Every shaft size is carefully calculated to be safe in operation during its lifespan. Class shafts comply with specific class rules and IACS requirements. Every sled keyed shaft is also spooned to avoid stress concentration points in the keyway.

MANUFACTURING

STRENGTH AND CORROSION RESISTANCE

Most shafts are manufactured with Marinemet 25 as standard, which is stronger and more resilient to corrosion than even surgical stainless steel. Other materials from 316L up to Super Duplex are available if required.

Generally, materials are sourced from mills specifically chosen by CJR for their quality to meet IACS requirements.

Shaft sizes are available from 30mm up to 180mm diameter and a length of up to 9m. Note that shafts in excess of 6m are not generally kept in stock by CJR or its stockholders, and lead times can be up to nine months.

Catalogs

No catalogs are available for this product.

See all of CJR Propulsion‘s catalogsRelated Searches

- Propeller

- Fixed-pitch propeller

- Boat propeller

- Propeller shaft propeller

- 4-blade propeller

- 3-blade propeller

- Bronze propeller

- Rudder blade

- 5-blade propeller

- Mechanical seal

- Propeller shaft mechanical seal

- Shaft

- Boat shaft

- Boat propeller shaft bracket

- Propeller shaft bracket

- Stern tube

- Boat stern tube

- Motor boat rudder blade

- Cutlass bearing

- Propeller shaft cutlass bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.