- Equipment

- Propulsion, Engine controls

- Boat propeller

- CJR Propulsion

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

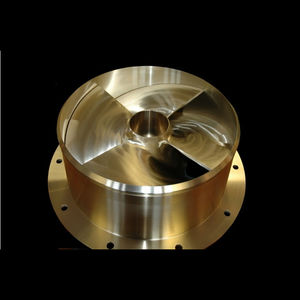

Boat propeller CJRfixed-pitchpropeller shaft3-blade

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Application domain

- boat

- Technology

- fixed-pitch

- Propulsion

- propeller shaft

- Number of blades

- 4-blade, 3-blade, 5-blade, 6-blade, 7-blade, 8-blade

- Material

- bronze

- Diameter

Max.: 1,500 mm

(59 in)Min.: 600 mm

(24 in)- Pitch

Max.: 1,200 mm

(47 in)Min.: 600 mm

(24 in)

Description

Every CJR propeller is designed to the highest quality standards and custom-made for the specific vessel in question using advanced design and production technology to do so. Our continuous investment in precision manufacturing technology is combined with a data and intelligence-led mindset, to deliver the ultimate in propulsion performance and efficiency as standard. Equally, every CJR propeller can be manufactured to any classification society rules, including all IACS societies for complete peace of mind.

Our unique end-to-end design and manufacturing process is unrivalled in Europe and leverages the latest in CFD and FEA design software, highly accurate pattern-less moulding, and five-axis CNC-machining to create truly bespoke propulsion solutions that deliver long-term benefits and efficiencies. This means every CJR propeller is designed without constraint, to the precise requirements of the vessel and its intended application.

Customers have reported saving as much as 10% in fuel costs per annum and have increased top speed by up to two knots simply by switching from a set of hand-finished props to a set of fully bespoke CJR fully CNC machined propellers.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Propeller

- Fixed-pitch propeller

- Boat propeller

- Propeller shaft propeller

- 4-blade propeller

- 3-blade propeller

- Bronze propeller

- 5-blade propeller

- Rudder blade

- Mechanical seal

- Propeller shaft mechanical seal

- Shaft

- Boat shaft

- Boat propeller shaft bracket

- Propeller shaft bracket

- Stern tube

- 6-blade propeller

- Boat stern tube

- Motor boat rudder blade

- Cutlass bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.