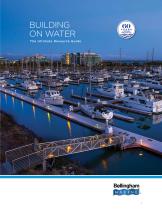

- Marinas

- Marina equipment

- Floating dock

- Cmferrer S.A. - Bellingham Marine Europe

Floating dock UNIDECK®mooringfor marinasfor harbor

Add to favorites

Compare this product

Characteristics

- Type

- floating

- Use

- mooring

- Applications

- for marinas, for harbor, boat, for special events

- Material

- aluminum

- Other characteristics

- custom

Description

The Unideck® system has been developed from the need to provide an economical solution for marinas in calm coastal locations and freshwater rivers and lakes. The design has proven its durability and is growing in popularity.

Bellingham's Unideck® system is perfectly suited to the needs in Europe and the Mediterranean Sea. For marinas with a rougher wave environment, the Unideck® product can be paired with the Unifloat® wave attenuator to meet the marina's needs.

The system utilizes a metal frame, typically aluminum, supported by floats. Although plastic floats are the most common the system can also be supported by concrete floats. The deck of the Unideck® system can be finished with a variety of materials including composites, hardwoods and concrete. There are also many fendering options available.

The Unideck® dock system is designed to be anchored by either pilling or chain anchors.

The Unideck® dock system offers a wide variety of options available allowing customers to create a truly customized product for their project.

Buoyancy: The number of floats required to take the loading is calculated for a single module, free of anchoring and all ancillary equipment loaded equal to the width of the deck visible to maintain the decking out of the water under a uniformly distributed load of 250 Kg / m² on the pontoon module.

Stability: This value is determined under the same conditions as the freeboard with loading for a live load applied over a half-width of the dock under a uniformly distributed load of 250 Kg / m².

Catalogs

Other Cmferrer S.A. - Bellingham Marine Europe products

Marinas and harbors

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.