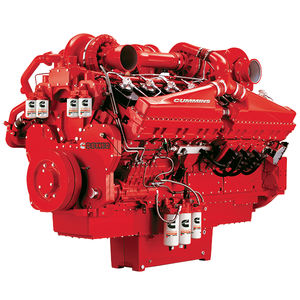

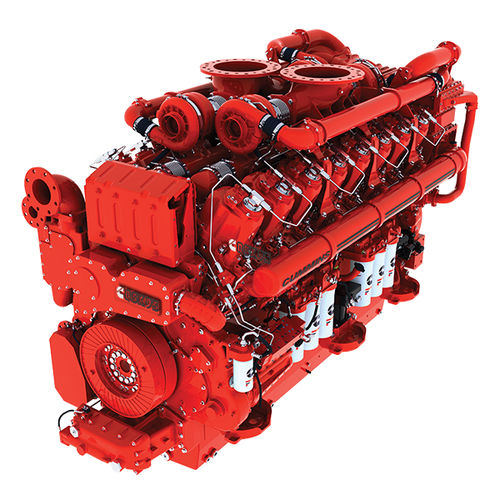

Inboard engine QSK95propulsionauxiliarydiesel

Add to favorites

Compare this product

Characteristics

- Type

- inboard, propulsion, auxiliary

- Power source

- diesel

- Market

- boating, professional vessel

- Technology

- turbocharged, common-rail

- Engine type

- V

- Rotation direction

- left hand

- Pollution control standard

- Tier 3

- Other characteristics

- 4-stroke

- Power

Min.: 3,200 ch

(3,200 hp)Max.: 4,200 ch

(4,200 hp)- Number of cylinders

16 unit

- Engine speed

1,500 rpm, 1,700 rpm

(9,425 rad.min-1, 10,681 rad.min-1)- Bore

190 mm

(7.5 in)- Stroke

210 mm

(8.3 in)- Length

3,654 mm

(144 in)- Width

1,733 mm

(68 in)- Height

2,362 mm

(93 in)- Weight

12,916 kg

(28,475 lb)

Description

The most powerful high-speed engine ever built for marine vessels

Compared to medium speed engines: lower capital cost, more compact installation and more cost-effective rebuilds

Designed to withstand the challenging conditions commercial marine operators often face; this same reliable, durable power is also available for recreational boating applications, including super yachts and yacht support vessels

In-cylinder technology to meet IMO Tier II and EU Stg. 3a; platform for future emissions in the U.S. and globally

Covered by a comprehensive one year warranty and backed by Cummins global service network

Built at Seymour Engine Plant in Seymour, IN, U.S.

Fuel System – High Pressure Common Rail Fuel System provides high injection pressure up to 2500 bar for quiet operation, idle stability, improved low-end torque and reduced emissions. Patented NanoNet™ filtration provides exceptional protection against fuel contamination

Cooling System – Two pump, two loop cooling system utilizes a dual impeller, single shaft pump with premium sealing technology. Titanium plate heat exchanger provides superior durability with minimal maintenance requirements

Exhaust System – Dry shielded exhaust manifold for reduced fuel consumption and improved performance

Air System – Cummins turbochargers optimized for marine applications. Two-stage aftercooling for efficient operation and optimization of performance

Lubrication System – ELIMINATOR™ self-cleaning oil filtration system replaces spin-on filters to reduce maintenance time and cost. Optional CENTINEL™ oil replenishment system extends oil change intervals.

Catalogs

Related Searches

- Inboard marine engine

- Diesel engine

- Professional engine

- 4-stroke engine

- Diesel generator set

- Turbocharged engine

- Professional vessel engine

- Boat generator set

- Propulsion motor

- Direct injection engine

- 50 Hz generator set

- Common rail engine

- In-line engine

- Ship engine

- Tier 3 engine

- Auxiliary engine

- Generator set with alternator

- Yacht generator set

- 60 Hz generator set

- V engine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.