- Equipment

- Safety

- Ship monitoring and control system

- Damen Marine Components

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Ship monitoring and control system BOSS™ BCMfor bearing clearance

Add to favorites

Compare this product

Characteristics

- Application domain

- for ships

- Applications

- for bearing clearance

Description

BOSS™ BCM is developed for the continuous measurement of the neck and carrier bearing clearance. This is done by electrical wires (sensors) that measure the real-time distance between the rudder-trunk and rudder-stock with 90° offset. These wires are routed inside the rudder-trunk and shielded by protection pipes.

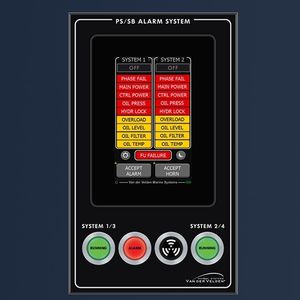

The measurements will be sent to the BOSS™ BCM display, which can be located in the e.g. the steering gear room, engine control room or wheel house. The information displayed contains the initial, maximum and current radial clearance of the neck bearing, the axial clearance of the upper bearing, a statistic of the wear-out pattern and a forecast of the remaining lifetime till replacement.

The data of BOSS™ BCM can be logged and uploaded in the cloud with BOSS™ DCC and DLF applications. Access to the logged data is possible with a smartphone or tablet at a remote location. This allows for e.g. DMC service engineers to keep track of the condition of the bearings and to execute condition inspections, direct failure analyses and quick repair jobs if required (predictive maintenance).

SPECIFCATIONS

ADVANTAGES

Continuously measures the neck and upper bearing clearance

Data can be accessed from a remote location on a smartphone or tablet

Provides a continuous and real-time insight into the condition of the bearings

All data can be logged and accessed in the cloud with BOSS™ DCC and DLF

SUITABLE FOR

All vessels with a rudder system, both newbuild and for retrofit

Catalogs

No catalogs are available for this product.

See all of Damen Marine Components‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.