- Equipment

- Safety

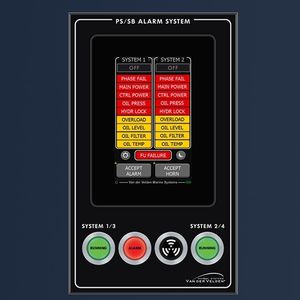

- Ship monitoring and control system

- Damen Marine Components

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Ship monitoring and control system BOSS™ OQMfor oil quality

Add to favorites

Compare this product

Characteristics

- Application domain

- for ships

- Applications

- for oil quality

Description

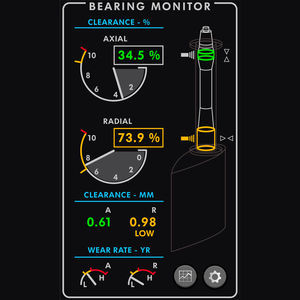

BOSS™ OQM is developed to continuously measure the oil condition of a hydraulic system. These measurements are performed by a sensor that is placed in the hydraulic system during installation.

The BOSS™ OQM measures and calculates the contamination, temperature and pressure of the hydraulic system(s). With the measured data of e.g. the steering system, the torque can be calculated and is continuously visible on the display of the OQM.

BOSS™ OQM allows insight into the past behaviour of the steering system and its oil condition. If, for example, the rudder forces of the vessel are suddenly disrupted, one can look into the past logged information in order to determine when and why such an incident occurred.

SERVICE MONITORING

If given permission by the customer/end user, DMC’s service engineers can directly connect to the BOSS™ OQM at all times to check the condition of the hydraulic system(s) and to perform condition inspections, direct failure analyses and predictive/preventive maintenance. This ensures maximum performance and minimal downtime of the vessel and its system(s).

It is advised to combine BOSS™ Dmc Cloud Connect (DCC) and Data Logging Function (DLF) with the OQM application to log and access the measured data. This allows to access past and present OQM measurements at all times and at a remote location.

SPECIFCATIONS

ADVANTAGES

Data can be accessed from a remote location on a smartphone or tablet

Allows insight into the past and present behaviour of the steering system

All data can be logged and accessed in the cloud with BOSS™ DCC and DLF

Continuously measures and displays the real-time condition of the hydraulic oil

Catalogs

No catalogs are available for this product.

See all of Damen Marine Components‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.