- Products

- Catalogs

- News & Trends

- Exhibitions

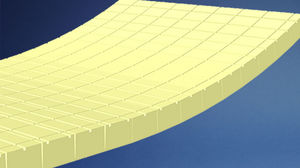

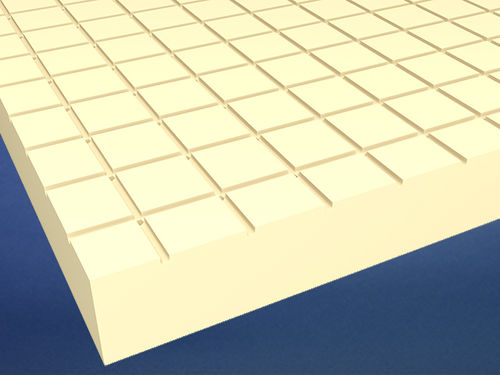

Grooved core material Flow vacuum infusion

Add to favorites

Compare this product

Characteristics

- Properties

- grooved

- Other characteristics

- vacuum infusion

Description

To distribute resin and evacuate air, there are several options. Diab has developed unique solutions especially suited to the needs of fast and secure vacuum-assisted manufacturing, so you can get the best performance out of every design.

Cuts or shallow grooves on the core surface will allow the resin to distribute and ensure good laminate wet-out. Perforations allow air evacuation, and in a vacuum infusion process, the perforations will transfer resin from one side of the core to the other, further ensuring proper laminate wet-out. Perforations are also used when working with prepreg, or when using core bedding adhesives. These finishes can be successfully combined with formable options.

Grooved and perforated combinations remove the need for an additional distribution medium within the laminate or above it. These finishes can be successfully combined with formable options such as grid-scored material.

Selecting the right finishing will impact not only the weight of the final component and surface quality, but can also speed up manufacturing time.

Diab will help you select the most efficient flow finishing based on your specific requirements.

Datasheets for all finishing options are available under Brochures, Datasheets & Certificates

Catalogs

Kitting

7 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.