- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Core material Form

Add to favorites

Compare this product

Description

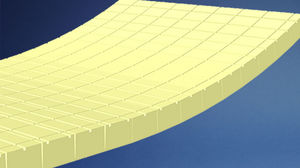

To create curves, you have formable finishing options. Diab has developed unique solutions especially suited to the needs of single- and double-curved geometries, so you can get the best performance out of every design.

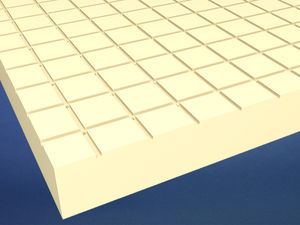

Grid-scored finish enables the core to conform easily to the mould for complex shapes. A square cut pattern creates small blocks that are held together by a lightweight fiberglass scrim. The core will not spring back when placed in the mould.

One-direction cut finish is similar to grid-scored, but with cuts in one direction only. Double-cut finish allows curvature into panels without applying a scrim. The core is cut in a 0–90 grid pattern on both sides through more than half of its thickness, also allowing air and resin to flow through the core.

Selecting the right finishing will impact not only the weight of the final component and surface quality, but can also speed up manufacturing time.

Diab will help you select the most efficient flow finishing based on your specific requirements.

Datasheets for all finishing options are available under Brochures, Datasheets & Certificates.

Catalogs

Finishing broshure

7 Pages

Kitting

7 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.