- Maritime equipment

- Deck equipment, Cargo handling

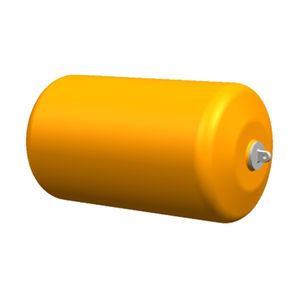

- Ship fender

- DOOWIN - Underwater Lift Bags & Water Weight Bags

Harbor fender for shipsfor docksfor docks

Add to favorites

Compare this product

Characteristics

- Application domain

- for harbor, for ships

- Applications

- for docks, for docks, heavy-duty, cushion

- Configuration

- cylindrical, custom

- Color

- black, white

- Material

- foam-filled

- Other characteristics

- closed-cell, chaine-tire net

Description

Foam fenders is one kind of tough heavy-duty and unsinkable floating fenders system. They are often used for harbor, offshore and ship-to-ship applications. Foam-filled fenders have higher energy absorption with lower reaction force. Its performance is higher than the pneumatic rubber fenders and other marine fenders. Its self-floating characteristic ensures foam fenders are workable for ship-to-ship operation.

Netless foam fenders are without the chain and tire net.

Netted foam fenders are with chain and tire net protection. +

Floating Foam Filled Fenders Construction

Foam-filled fenders are filled with resilient, closed-cell foam. The skin is constructed of a urethane elastomer reinforced with nylon mesh.

foam filled fenders construction

HIGH ENERGY ABSORPTION FOAM CORE

The foam core is high-performance and quality 100% closed-cell foam, combined with our special laminating process, ensures the integrity of every fender core. This specific foam can provide high energy absorption with a relatively low reaction force. Even if the skin is punctured, it also is unsinkable without absorbing water.

TOUGH OUTER SKIN

Donut fenders have a rugged polyurethane elastomer outer skin, with nothing to snag hull protrusions or dock fittings. To provide added strength, the thick skin is reinforced with nylon mesh.

HIGH QUALITY STEEL STRUCTURE

Comprising through central steel tube and external load distribution flanges at each end. Heavy duty internal chain connecting the end fitting through central tube is applied to transmit tensile load through the fender. All end fitting of foam filled fenders are hot-dip-galvanized.

Catalogs

No catalogs are available for this product.

See all of DOOWIN - Underwater Lift Bags & Water Weight Bags‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other DOOWIN - Underwater Lift Bags & Water Weight Bags products

Foam Filled Fenders

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.