- Ship and boat building

- Production machines and tools

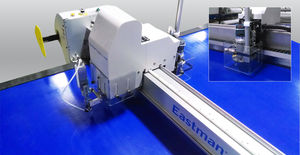

- CNC cutting table

- Eastman Machine Company

CNC cutting table Combi Laserlasermulti-axisblade

Add to favorites

Compare this product

Characteristics

- Type

- CNC, laser

- Number of axes

- multi-axis

- Treated material

- blade, metal, for composite fiber fabric

- Application domain

- for shipyards

Description

Combi Laser – Cutting Static Table

The Eastman combination laser and cutting system offers a laser for cutting fabrics that require a fused edge as well as the proven, reliable technology of Eastman’s static cutting table. The tool head is equipped with a 200 watt gas assist laser (100 watt optional), three individually aligned and calibrated tool spindles, and a pneumatic pen/marker holder. The static table system is available in a range of system lengths and widths to meet the demands for prototypes, one-offs and full-production runs. The system’s high-precision configuration features multi-axis motion for more defined and accurate cuts. Material is spread across the static table by an operator.

Cut, mark, punch and seal edges all on one system

Laser provides cintered edge to prevent fraying - great for materials like nylon and other materials that unravel.

Single gantry design offers three cutting tools, a laser and a marking tool, minimizing switchover time between material files and set up. (Laser and blade cutting cannot be performed simultaneously).

200 watt laser has no contact with the fabric, improving the quality and speed of the cut

Adjustable laser power within software, reducing unnecessary operating costs

Cutting Surface

The standard surface for cutting with the laser is a perforated honeycomb core metal table top. A supplemental table surface is supplied as a roll-down for use when cutting with traditional blades.

International Compliance Ratings

The operating computer and control cabinet are housed in an ergonomic enclosure that can be sealed to offer dust and water resistant protection in harsh or high particulate environments.

VIDEO

Catalogs

Combi Laser

1 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Eastman shipyard cutting machine

- Eastman electric cutting machine

- Eastman rotary-knife cutting machine

- Eastman fabric cutting machine

- Eastman cutting table

- Eastman shipyard cutting table

- Eastman CNC cutting table

- Eastman plastic cutting machine

- Shipyard cutting tool

- Pneumatic cutting machine

- Control software

- Rubber cutting machine

- Eastman shipyard storage rack

- Eastman spreading machine

- Shipyard software

- Eastman spreading machine with cutting system

- Carpet cutting machine

- Conveyor cutting table

- Nesting software

- Straight-knife cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.