- Ship and boat building

- Production machines and tools

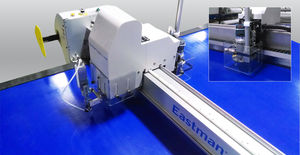

- CNC cutting table

- Eastman Machine Company

CNC cutting table C135 conveyorfor plasticsfor fabric

Add to favorites

Compare this product

Characteristics

- Type

- CNC, conveyor

- Treated material

- for plastics, for fabric

- Application domain

- for shipyards

Description

The Eastman Eagle C135 conveyor system boasts supreme capabilities for single- to low-ply cutting requirements. It has the ability to continuously convey rolled material goods with consistent speed and control. Eastman’s gantry and tool head design are engineered to cut the most diverse technical and industrial fabrics available, while exceeding industry standards for accuracy.

The robust conveyor design delivers unrivaled levels of material utilization and is often capable of cutting multiple layers without plastic overlay. This computer-controlled cutting system requires minimal operator guidance to automatically feed and spread material to the identified start position. The C135 offers tremendous efficiency when cutting pattern pieces that exceed the table length. The exclusive InMotion™ software enables the machine to continuously cut while conveying.

Available in a range of widths, lengths and various tool head accessory options, the C135 will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

Standard Features

Choice of standard, heavy-duty or fiber tool head, featuring individually aligned and calibrated tool spindles with your choice of over 60 blades, punches and notches.

A library feature within the operating control software allows the operator to save commonly used tool pressures and blade assignments based on job and material files.

Prevent unauthorized changes to the system and software with restricted login access.

Cutting Surface

The cutting surface is a smooth and durable, high-durometer cast urethane conveyor belt suitable for even sticky or downy materials.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Eastman Machine Company‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Eastman shipyard cutting machine

- Eastman electric cutting machine

- Eastman rotary-knife cutting machine

- Eastman fabric cutting machine

- Eastman cutting table

- Eastman shipyard cutting table

- Eastman CNC cutting table

- Eastman plastic cutting machine

- Shipyard cutting tool

- Pneumatic cutting machine

- Control software

- Rubber cutting machine

- Eastman shipyard storage rack

- Eastman spreading machine

- Shipyard software

- Eastman spreading machine with cutting system

- Carpet cutting machine

- Conveyor cutting table

- Nesting software

- Straight-knife cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.