- Ship and boat building

- Production machines and tools

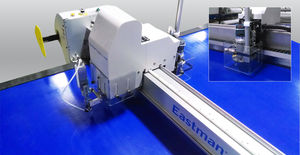

- CNC cutting table

- Eastman Machine Company

CNC cutting table Talon 25conveyorfor composite fiber fabricfor fiberglass

Add to favorites

Compare this product

Characteristics

- Type

- CNC, conveyor

- Treated material

- for composite fiber fabric, for fiberglass, fiberglass

- Application domain

- for shipyards

Description

The Talon offers an industrial-strength solution for high-ply production facilities with capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Eastman Talon Multi-Ply is engineered and manufactured in the USA to automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Precise system operations with state-of-the-art motion control communications offer an industrial-strength solution. The Talon 25 can cut up to 1.18 in. (3 cm) of compressed material goods, while the Talon 75 has the capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Talon has been engineered to meet the demands of clients in growing market segments like industrial fabrics and composites industries; customers cutting traditional -as well as- modern technical materials like kevlar, fiberglass, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

Materials database

Power consumption reduced through intelligent vacuum controls

Washable filters

Internal silencer

Tool Head

The Talon Tool Head, patent pending

Quick change knife and sharpening disc

Reciprocating knife provides precise vertical stroke cutting

Intellicut knife control software ensures high-quality, precise cuts from top to bottom ply (75x only)

Talon 25: can cut up to 1.18 in. (3 cm) of compressed material goods

Talon 75: can cut up to 3 in. (7 cm) of compressed material goods

Single coated diamond disc provides the perfect cutting edge. Sharpener can be adjusted to user defined angle.

High-speed-single or dual pneumatic drills

Internal crank cooling system reduces heat and wear/tear

VIDEO

Catalogs

No catalogs are available for this product.

See all of Eastman Machine Company‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Eastman shipyard cutting machine

- Eastman electric cutting machine

- Eastman rotary-knife cutting machine

- Eastman fabric cutting machine

- Eastman cutting table

- Eastman shipyard cutting table

- Eastman CNC cutting table

- Eastman plastic cutting machine

- Shipyard cutting tool

- Pneumatic cutting machine

- Control software

- Rubber cutting machine

- Eastman shipyard storage rack

- Eastman spreading machine

- Shipyard software

- Eastman spreading machine with cutting system

- Carpet cutting machine

- Conveyor cutting table

- Nesting software

- Straight-knife cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.