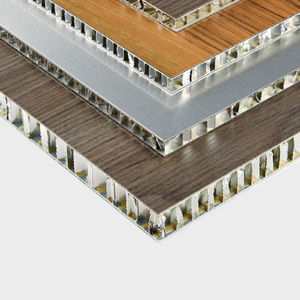

Ship partition wall sandwich panel ALU SERIESfor ship floorsfor ship ceilingsaluminum honeycomb

Add to favorites

Compare this product

Characteristics

- Applications

- for ship partition walls, for ship ceilings, for ship floors

- Core

- aluminum honeycomb

- Facing

- aluminum

Description

ALUCELL panels of the ALU series are characterized by the coating made of primer coated, anodised or pre-painted aluminum sheets (PE, PA, PVDF, liquid or powder paint cycle) coupled by gluing to the aluminum honeycomb core.

The sheets in primer coated aluminum are coated with a thin layer of primer to favor the possible coating with other finishes (HPL plastic laminate, varnishes, leathers, carpets, etc.), while the pre-painted or anodized sheets give the product an excellent finish aesthetics. Thanks to the good performance / cost ratio, ALUCELL panels with primer coated skins are used as a support for coatings to create interior walls, false ceilings, floors, furniture elements, etc.

ALUCELL panels of the ALU series are certified as material with limited flame spread as per directive MED 96/98/CE and subsequent changes. changes. When used with an appropriate extruded profile system, ALUCELL ALU series panels can be used to make certified Class C bulkheads.

All qualitative properties of ALUCELL panels

Excellent resistance to bending and to shear and tensile stresses.

Excellent flatness and dimensional stability.

High Ratio mechanical performance / weight.

Good chemical resistance and resistance to atmospheric agents.

Easy to work with common tools for aluminum or wood.

Good resistance to paint systems within hot air oven (180 °C).

Catalogs

ALU SERIES

3 Pages

HPL SERIES

3 Pages

Related Searches

- Sandwich panel

- Ship partition wall sandwich panel

- Wood sandwich panel

- Ship fitting sandwich panel

- Honeycomb sandwich panel

- Metal sandwich panel

- Foam sandwich panel

- Aluminum sandwich panel

- Decorative sandwich panel

- Interior floor sandwich panel

- Ship ceiling sandwich panel

- Plywood sandwich panel

- Ship floor sandwich panel

- Okoumé sandwich panel

- Cork sandwich panel

- Construction sandwich panel

- PET foam sandwich panel

- Steel sandwich panel

- Stainless steel sandwich panel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.