- Equipment

- Propulsion, Engine controls

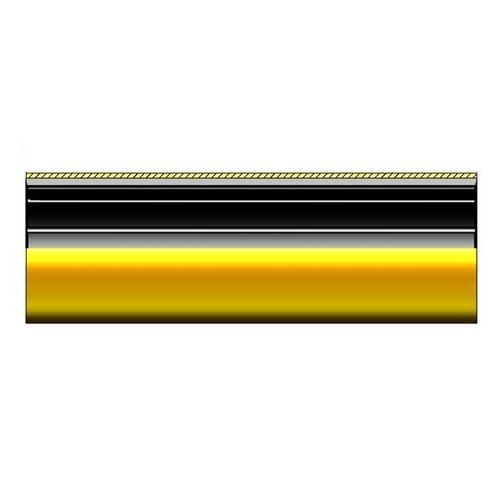

- Brass cutlass bearing

- Italian Propellers S.r.l.

Rubber cutlass bearing resinbrassfor propeller shafts

Add to favorites

Compare this product

Characteristics

- Material

- rubber, resin, brass

- Applications

- for propeller shafts

Description

The water-lubricated bearing are made with an outer bearing of brass (OT63) or technoplastic polyamide

resin that has the advantage of neutralising electrolytic corrosion.

The inside of the bearings are coated with black nitrile rubber with the following characteristics:

Density = 1.23

Hardness = 70/75 shore

Tensile strength at break = 2,2 Kg/mm²

Elongation at break = 225%

Suitable for shafts with forward and reverse rotation.

The bearings are lubricated with water that forms a very thin film between the shaft and rubber of the bearings, and reduces the coefficient of friction to very low values. Never run dry because a high temperature would immediately damage the bearing. Make sure the rubber does not come into contact with harmful substances, such as grease or lubricating oil. The circulation water contributes to evacuating the heat from the inner surface of the bearing, whose temperature must never exceed 50/60°C.

Therefore, it is necessary to:

Leave a minimum clearance between the shaft and rubber bearing, which should vary depending on the diameter (0.10 to 0.30 mm).

Make sure the peripheral speed of the shaft does not drop below 0.2 m/sec.

Keep the necessary amount of circulating water by installing an independent sea cock.

Catalogs

No catalogs are available for this product.

See all of Italian Propellers S.r.l. ‘s catalogsRelated Searches

- Propeller

- Fixed-pitch propeller

- Boat propeller

- Propeller shaft propeller

- 4-blade propeller

- 3-blade propeller

- Coupling

- Bronze propeller

- Shaft mechanical coupling

- Ship coupling

- Aluminum propeller

- Boat coupling

- 5-blade propeller

- Rigid mechanical coupling

- Rudder blade

- Ship propeller

- Yacht propeller

- Shaft

- Nickel propeller

- Flange mechanical coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.