- Equipment

- Propulsion, Engine controls

- Flange mechanical coupling

- jbj Techniques Limited

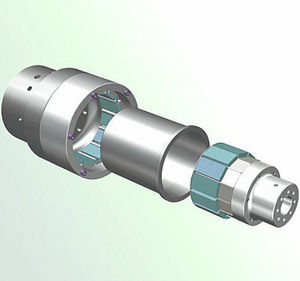

Flexible mechanical coupling flangetorsionally flexibleelastomer

Add to favorites

Compare this product

Characteristics

- Type

- flexible, flange, torsionally flexible, elastomer, jaw

- Application domain

- for boat, for ships

- Applications

- for shafts

- Other characteristics

- misalignment correction, anti-vibration, shaft-hub, torque, non-lubricated, compensating, large-size, high-torque, with high torsional flexibility, zero-backlash, 3-part

Description

Large stocks for quick delivery and in-house machine shop for exact fit to your application machinery.

Telephone: +44 (0)1737 767493 or email: info@jbj.co.uk

The flexibility of the drive ring allows the power transmission coupling to compensate for parallel, angular and axial displacements.

Maximum shaft diameters of 145 mm can be accommodated with maximum torques up to 15,000 Nm and maximum speeds of 19,000 rpm.

• Torsional elasticity

• Dampening

• Blind assembly

• Safe against break-down

• No maintenance

• Hub material: Aluminium (Al), Cast Iron (GG/GGG), Sintered Steel (Si), Steel (St).

The important information you need for these spider / jaw type mechanical power transmission couplings: below you will find~

» Service factors (link).

» Displacement values (link).

» Torque ratings (link).

» Increase the life of your spider coupling elements (link).

Spidex power transmission couplings are torsionally flexible shaft couplings, the operating characteristics of which are two hubs with concave claws, transmitting the torque by meshing with an elastic involute gear ring.

The spider coupling concept gives a reliable, smooth power transmission without torsional oscillation / vibration and so protects the connected machinery.

Due to the complete flexibility and ductility of the elastomer ring, it compensates for parallel and angular displacements as well as to absorb longitudinal movement of the shafts.

The involute teeth of the elastomeric inserts are crowned in order to avoid edge pressure on the tooth flanks and so avoid undesirable axial thrust.

Catalogs

No catalogs are available for this product.

See all of jbj Techniques Limited‘s catalogsOther jbj Techniques Limited products

bellhousings / couplings

Related Searches

- Motor reduction gearbox

- Boat reduction gearbox

- Ships reduction gearbox

- Coupling

- Shaft mechanical coupling

- Ship coupling

- Boat coupling

- Flexible mechanical coupling

- Rigid mechanical coupling

- Flange mechanical coupling

- Anti-vibration mechanical coupling

- Torque mechanical coupling

- ATEX mechanical coupling

- Elastomer mechanical coupling

- Shaft-hub mechanical coupling

- Torsionally flexible mechanical coupling

- Torsionally rigid mechanical coupling

- Compact mechanical coupling

- Non-lubricated mechanical coupling

- Compensating mechanical coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.