- Equipment

- Propulsion, Engine controls

- Torsionally flexible mechanical coupling

- jbj Techniques Limited

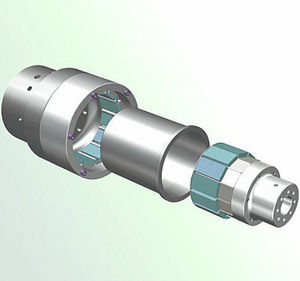

Rigid mechanical coupling LF SERIEStorsionally flexibleelastomerjaw

Add to favorites

Compare this product

Characteristics

- Type

- rigid, torsionally flexible, elastomer, jaw, torsionally rigid

- Application domain

- for boat, for ships

- Applications

- for shafts

- Other characteristics

- shaft-hub, anti-vibration, large-size, backlash-free, non-lubricated, torque, high-performance, misalignment correction, compensating, heavy-duty, large, low noise and vibration, high-speed, variable-speed, maintenance-free, high load capacity, with high torsional flexibility, flywheel

Description

Dampen torsional vibrations and tune mechanical power transmission systems to have critical speeds outside the operating range.

» Solve torsional vibration problems within Diesel engine applications.

» Torsionally flexible or rigid dependant on application.

» Low weight, low moment of inertia.

» Small overall length aids equipment design.

» Enables disassembly without moving driver/driven equipment.

» Flanged versions suit SAE standard and non-standard arrangements.

» LM series design protects driver/driven equipment under stall condition.

This range of torsional couplings solve torsional vibration problems typical of those found in diesel engine applications. The torsional coupling dampens torsional vibrations and tunes the system to have critical speeds outside the operating range.

jbj Techniques Ltd can analyse the application and determine the exact torsional coupling needed for almost any application.

LF torsional couplings

Substantial shock, vibration and misalignment capabilities, maintenance free, fail-safe operation.

Characteristics and benefits of LF Torsional Couplings

The basic component of the LF torsional coupling from jbj Techniques is the unique and highly versatile elastomeric element (1).

This element can be easily mounted in a number of different ways depending on the application, and without special design changes or complex hardware modifications. The element, which is available in different materials for optimum performance, is connected to a cylindrical hub (2) with radial screws (3) and then to a flanged hub by axial (4) screws. This unique coupling design is remarkably simple, highly effective

Catalogs

No catalogs are available for this product.

See all of jbj Techniques Limited‘s catalogsOther jbj Techniques Limited products

bellhousings / couplings

Related Searches

- Motor reduction gearbox

- Boat reduction gearbox

- Ships reduction gearbox

- Coupling

- Shaft mechanical coupling

- Ship coupling

- Boat coupling

- Flexible mechanical coupling

- Rigid mechanical coupling

- Flange mechanical coupling

- Anti-vibration mechanical coupling

- Torque mechanical coupling

- ATEX mechanical coupling

- Elastomer mechanical coupling

- Shaft-hub mechanical coupling

- Torsionally flexible mechanical coupling

- Torsionally rigid mechanical coupling

- Compact mechanical coupling

- Non-lubricated mechanical coupling

- Compensating mechanical coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.