- Water sports

- Kayaking, Rowing, Canoeing

- Racing shell

- Kaschper Racing Shells

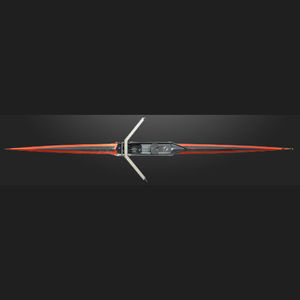

Racing shell Raven single scull

Add to favorites

Compare this product

Characteristics

- Intended use

- racing

- Type

- single scull

Description

The RAVEN model single was designed specifically for ELITE competition. The focus was on creating superior structural integrity by combining the inherent strength and resilience of a 100% CARBON HULL with the newest RESIN INFUSION production techniques. The result is a lighter and more perfectly balanced shell, as all excess resin is REMOVED in the controlled infusion process! (This same excess resin remains in a pre-preg layup shell and increases it's finished weight needlessly. By switching to infusion we eliminate the inefficient and fragile prepreg and honeycomb process that is still a standard for many manufacturers.) INFUSION is accomplished by drawing EPOXY RESINS through the CARBON FIBER layers under vacuum while in the mould. This is followed by DOUBLE CURING in our high temperature oven. To enhance structural integrity further, we continue to use our highly successful Kaschper UNIDECK SYSTEM. By moulding the entire cockpit and decks as single units without joints, we increase overall product stiffness, which augments strength and extends longevity. Each RAVEN is then CLEAR COATED and POLISHED to feature it's unique CARBON FABRIC pattern.

RAVEN is fitted with all Top Line Kaschper-crafted components. These include our new reinforced T-WING RIGGER; RIGGER MOUNT; FLEXBOARD FOOTSTRETCHER, and extra long TRACKS in Lightweight Aluminum. All are Hard Coat Anodized for extra protection in Salt water. The REACTIV SEAT is designed to support the sculler and reduce pressures on the Hamstrings and the Base of the Spine. It is fitted with the new Kaschper designed SEALED STAINLESS STEEL BEARING WHEELS that provide smooth, stable slide movement.

Catalogs

No catalogs are available for this product.

See all of Kaschper Racing Shells‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.