- Ship and boat building

- Production machines and tools

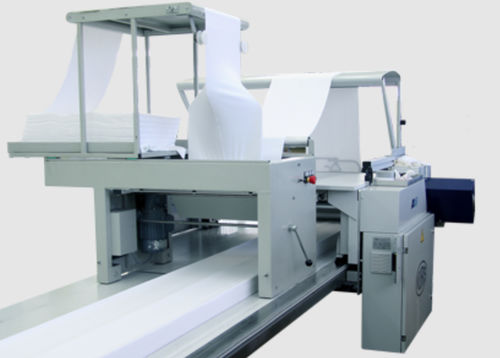

- Spreading machine with cutting system

- Kuris Spezialmaschinen

Spreading machine with cutting system A16

Add to favorites

Compare this product

Characteristics

- Options

- with cutting system

Description

Special spreading machine for semi and fully automatic spreading of folded or rolled tubular fabric equipped with expanders and as option with crease changing device.

The compact KURIS tubular spreading machine A16 is a special system for semi and fully automatic spreading of tubular fabric. The user interface via touch-screen concept is easily operable. Thanks to a programmable, multi-stage driving profile the system is featuring optimal dynamic driving characteristics. The low construction offers the customer a wide view field during the spreading process. The tubular spreading device including special calender rolls has a separate adjustment possibility for the contact pressure on both sides – the roll gap is opened via an eccentric crank. The higher-level micro processor regulates via the controlled gears a precise synchronisation between the fabric pre-feeding and travel drive. The integrated frequency transformers secure an exact and wrinkle free spreading. With the threading aid the fabric can be thread without problems. The motorised aggregate lift is integrated to achieve spreading heights up to 230 mm.

ADVANTAGES AT A GLANCE:

Big, low and easily accessible platform for folded fabric, 900 mm depth

The fabric-deflector and the expanders for r olled or folded material are adjustable

Torsion-resistant light chassis

All-wheel-drive with PUR-rollers

Operation via touch-screen / Windows basis

Easily operable threading aid

Rotary handle for speed regulation

Operator’s travel-on platform with safety stop

OPTIONS:

Operator’s travel-on platform alternatively with support bracket or seat

Unrolling device for rolled tubular fabric

Catalogs

A16

2 Pages

Related Searches

- Shipyard cutting machine

- Electric cutting machine

- Rotary-knife cutting machine

- Textile cutting machine

- Cutting table

- Shipyard cutting table

- CNC cutting table

- Plastic cutting machine

- Pneumatic cutting machine

- Rubber cutting machine

- Leather cutting machine

- Spreading machine

- Spreading machine with cutting system

- Battery-powered cutting machine

- Conveyor cutting table

- Straight-knife cutting machine

- Vacuum cutting table

- Cutting and spreading table

- Multi-ply fabric cutting table

- Textile cutting table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.