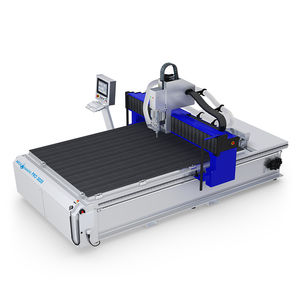

CNC machining center MECAPLUS HP3-axisverticalmetal

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Treated material

- metal, for composites, for resin, for aluminum, brass, for plastics, for PVC, for foam, for plates, for steel, for soft materials

- Performance

- high-speed

- Associated function

- cutting, drilling, milling, thread

Description

MECAPLUS HP

MECAPLUS-HP “AGILE” MACHINING High precision and performance solution

HIGH PRODUCTIVITY 3 axes milling equipment : “AGILE” MACHINING

STRENGTHS

Designed and realized for an intensive use.

Heavy, fast, powerful, precise and efficient equipment, easy to operate for the machining of rigid sheetmaterials of strong thickness, in the fields of plastic processing, modelling, aeronautics, aluminium processing… or for the machining of molds and 3D models.

Particularly adapted for the machining of aluminium, plastic materials of strong thickness and composite materials with high mechanical properties.

Many customization possibilities.

Innovative and efficient vacuum tables with turbine technology or vacuum pumps.

Numerical controls SIEMENS or HEIDENHAIN type.

Quality kinematics integrating industrial components supplied by the world leaders in their field, mounted on welded stabilized steel frames.

OPTIONS

Vacuum table technology with two-stage side channel turbine 7.5 kW, 520 m³/h

Vacuum table technology with four-stage turbine 15 kW, 1500 m³/h

Vacuum table with vacuum pump 250 m³/h, 4.5 kW

Tool cooling systems (frozen air, lubrication…)

Chip and dust suction systems

On-gantry rotating tool shop, capacity 24 tools (option 40 tools)

Rigid tapping

Heidenhain pressurized measurement rules on X, Y and Z axes...

TECHNICAL DESCRIPTION

Structure: high inertia steel welded mobile gantry.

Table Top: aluminium table with consumable covering or phenolic resin plate.

Guidance: precision linear rails with preloaded ball slides on 3 axis.

Transmission: Ballscrews on the 3 axis. Double ballscrew for the X axis.

Motorisation: Brushless motors.

PERFORMANCE

Catalogs

No catalogs are available for this product.

See all of MECANUMERIC‘s catalogsRelated Searches

- Shipyard cutting machine

- Electric cutting machine

- Textile cutting machine

- Machining center

- CNC machining center

- Milling machining center

- Vertical machining center

- 5-axis machining center

- Plastic cutting machine

- 4-axis machining center

- Pneumatic cutting machine

- Composite machining center

- Rubber cutting machine

- Cutting machining center

- High-speed machining center

- Leather cutting machine

- Wood machining center

- Resin machining center

- Plastic machining center

- Aluminum machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.