- Products

- Catalogs

- News & Trends

- Exhibitions

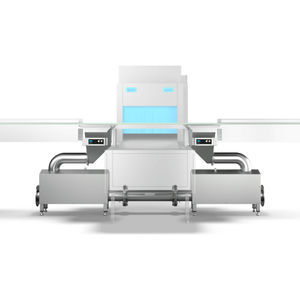

Food waste treatment system BioMaster®for ships

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Use

- food waste

- Application domain

- for ships

Description

Our pumped waste systems use a process of homogenisation to convert kitchen scraps and leftovers into a liquid biomass before it even leaves the infeed station. The biomass is then pumped through a sealed system of plastic piping into a storage tank. It is then held in the tank without releasing any odours until a tanker arrives to transport it to a biogas plant. Based on tried-and-tested technology, our pumped waste systems offer a flexible and easy-to-install solution. And we've even made it easy to incorporate grease traps, so you can combine everything in one system.

From processing powerhouses to lean and nimble all-rounders, our BioMaster® series infeed stations are available in a wide range of formats to suit any kitchen environment. They are the core components of our pumped waste systems – and a great addition to any kitchen!

Improved hygiene with less cleaning

Easy to handle

Efficient workflows

Self-contained system for safety

Longer collection intervals (fewer lorry journeys)

Synergy effects due to integration of the grease separator

Versatile tank solutions with no need for refrigeration

Minimises cutlery loss

Low disposal costs

High end in every way: our most efficient infeed station for all types of kitchen waste and leftovers. A standard programme and a programme for mainly dry food waste provide optimal conditions for efficient comminution and then storage of the food waste..MEIKOGREEN's innovative homogenisation technology delivers process reliability with minimal consumption of process water..

Catalogs

No catalogs are available for this product.

See all of MEIKO Maschinenbau‘s catalogsOther MEIKO Maschinenbau products

FOOD WASTE TREATMENT SYSTEMS FOR KITCHENS SMALL AND LARGE

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.