- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

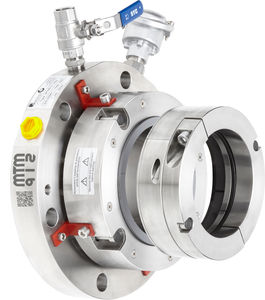

Propeller shaft mechanical seal MTM 400for shipsboatfor yachts

Add to favorites

Compare this product

Characteristics

- Applications

- for propeller shafts

- Application domain

- for ships, boat, for yachts

- Other characteristics

- electronic control

Description

It is surely the more resistant propeller shaft seal on the market. The MTM400, in comparison with all the existing propeller shaft mechanical seals, is the first in the world to be equipped with a double series of springs. This allows it to better compensate for angular and radial misalignments. Moreover, springs together with a double system of O-rings give rise to what Microtem has named DEDaS® (Double Elastic Damping System), that is an elastic damping system able to make the MTM400 resistant to 60 g shock and to 60 mm/s (RMS) of vibration. Inside of it, in the rotating part, there is another international recognized innovation: the pumping ring. This technology, newly introduced in the propeller shaft seals, ensures that the cooling fluid (usually water) is distributed to a greater and better extent on the sliding faces, increasing the heat dissipation and thus reducing consumption. All this allows MTM400 to achieve performance over 60.000 hours of operation before maintenance. Of equal importance is the design, as its compact size allows the seal to be one of the axially smaller solutions in the world. Additionally, the MTM400 together with the dynamic pneumatic barrier (Watershield®) is the most reliable and strong solution available today on the market. It is designed for shafts with diameter 50 mm to 800 mm, and it is certified by RINA. There are different possible material configurations and it is the only product fireproof. The stationary flange can be designed with a maximum of 6 radial holes that allow to connect: one or more auxiliary cooling lines for the bearing, a pressure gauge, a temperature gauge, a flow gauge or an axial/radial vibration sensor.

Catalogs

General catalogue

86 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.