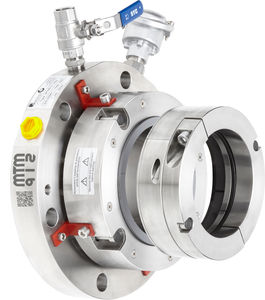

Propeller shaft mechanical seal MTM990 for shipsfor boatelectronic control

Add to favorites

Compare this product

Characteristics

- Applications

- for propeller shafts

- Application domain

- for ships, for boat

- Other characteristics

- electronic control

Description

The MTM990 propeller shaft seal is the world's first magnetic propeller shaft seal device. Compact, customizable in size and configuration, it is the first device to ensure that the rotating and stationary part are sealed by magnetic attraction. This ensures that the thrust of the stationary part on the rotating one is always constant and independent of the change in position of the propeller shaft respect to the stern tube. The system, unlike the bellows or spring mechanical seals, has no wear limits due to the loss of elasticity. The stationary case can accommodate up to 6 radial holes (optional) that can be used to connect: an additional flush, a temperature sensor, a vibration sensor (triaxial), a pressure sensor or a dedicated vent line. The stationary part, made of techno polymer standard, can be fixed to the tube by means of a series of grub screw or a clamp. The stationary ring can be supplied in resin graphite (G2) or in antimony graphite (G3) and inserted in a 316 stainless steel case. The rotating ring is constrained to the propulsion shaft with a series of grub screw (up to diameter 100) or with a clamp (over diameter 100) and is available in Duplex or Super Duplex. The integrated preload system guarantees extremely easy installation that does not require any particular specialization.

OPERATING LIMITS:

D= 70 – 215mm

P1= 2 bar

T= -30 a + 90°C

V= 20 m/s.

Axial movement: up to +/- 10.0 mm

Radial movement: up to +/- 5.0 mm

Angular movement: up to 2°

ELASTOMERS MATERIAL:

Epdm (E)

Nbr (N)

FLANGE MATERIAL:

Aluminum (AL)

Stainless steel 316 (J1)

Duplex (D)

Super Duplex (D1)

FACES MATERIAL:

Resin carbon graphite insert (G2)

Catalogs

No catalogs are available for this product.

See all of Microtem ‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.