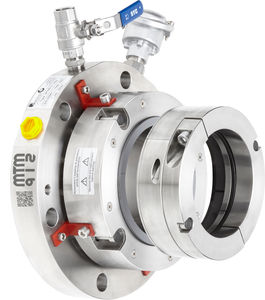

Propeller shaft mechanical seal MTM907for boatfor shipsfor yacht

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for propeller shafts

- Application domain

- for boat, for ships, for yacht

Description

The propeller shaft seal MTM907 was created to attack the market of medium / large boats and represents the product with the best value for money, available on the world market, in its category. Thanks to its design, it is the world’s most dynamic compact safety barrier split shaft seal. The stationary flange, foreseen for those who use flanged stern tube, is by standard in 316 Stainless Steel and can accommodate up to 6 radial holes (optional) in which it is possible to connect: an additional flushing, a temperature sensor, a vibration sensor (triaxial ), a pressure sensor or a dedicated vent line. The size of the flange, the number, the spacing and the pitch center distance can be customized according to the needs. The stationary ring can be supplied in Silicon Carbide (S1) or in Tungsten Carbide (T1) and is foreseen inserted in a 316 stainless steel case. the rotating case provided in 316 stainless steel with insert in Graphite Resin (G2), Graphite Antimony (G3), Silicon Carbide (S1) or Tungsten Carbide (T1). Thanks to SpliTEM® technology, the sliding rings (stationary and rotating), made in two halves, allow maintenance to be carried out directly in the water and / or with the propulsion axis in position, with a clear saving of time and money. . The Watershield® pneumatic dynamic barrier ring makes the MTM903 the most technologically advanced product in the propeller shaft seal market. The integrated preload system guarantees an extremely simple installation that does not require any particular specialization.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.