- Products

- Catalogs

- News & Trends

- Exhibitions

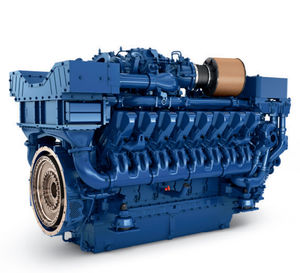

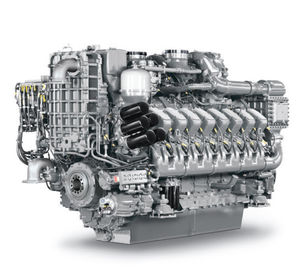

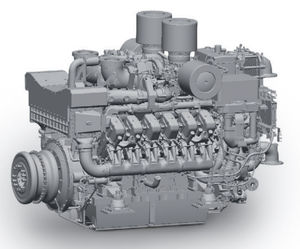

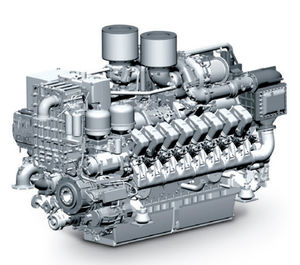

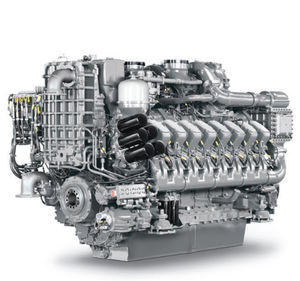

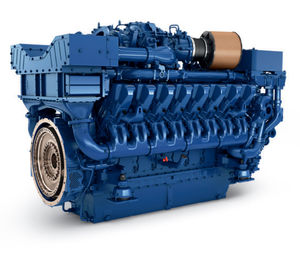

Inboard engine Series 4000 M05-Npropulsiongascommercial

Add to favorites

Compare this product

Characteristics

- Type

- inboard, propulsion

- Power source

- gas

- Market

- commercial

- Technology

- turbocharged

- Power

Max.: 2,682 ch

(2,682 hp)Min.: 1,000 ch

(1,000 hp)

Description

Standard equipment

Starting system Electric starter motor 24V, 2 pole, coolant preheating system

Oil system Gear driven lube oil pump, switchable oil filter, lube oil heat exchanger, pump for lube oil

extraction, closed crankcase ventilation, oil level monitoring

Cooling system Separate high and low temperature cooling circuit, engine version for separate heat

exchanger, gear driven coolant circulation pumps

Combustion air system Engine coolant temperature-controlled intercooler, turbocharging with 2 water-cooled

turbochargers, on-engine seawater-resistant air filters, 30° discharge elbow

Fuel system

Flexible positionable Gas Regulating Unit aligned with engine safety concept, containing

Gas-pressure regulating valve in accordance with engine requirements, monitored

gas-filter, Doubleblock&Bleed valves with second enclosure applicable for air ventilation

only. Tight secondary enclosure around fuel-system complying with gas-safe machinery

space, applicable for overpressure nitrogen and air ventilation (engine only), additional

on-engine gas filter, multi-point injection valve on each cylinder, modular built common

rail system on each cylinder bank, single fuel supply interface on engine connected via

flexible hose, flame arrestors in charge-air manifold

Engine management system Engine control and monitoring system (ADEC); engine interface module - EIM,

engine mounted

Mounting system Resilient engine mounting

Engine safety system The scope of delivery for the engine fulfils the requirements to be used in a gas safe

engine room design and SOLAS requirements for admissible temperature

Power transmission Torsional resilient and off-set compensating coupling

Catalogs

Marine & Offshore

53 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.