- Yachting

- Luxury yachts

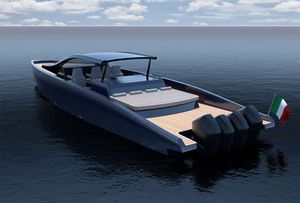

- Cruising motor yacht

- Mylius Yachts

Cruising motor yacht M62PflybridgewheelhouseIPS

Add to favorites

Compare this product

Characteristics

- Intended use

- cruising

- Deck layout

- flybridge, wheelhouse

- Propulsion

- IPS

- Number of cabins

- 2-cabin

- Maximum berth number

- 4-berth

- Hull type

- semi-displacement hull

- Material

- carbon

- Length

19.5 m

(63'11" )- Width

5.6 m

(18'04" )- Draft

1.5 m

(4'11" )- Cruising speed

18 kt

- Max speed

28 kt

- Fuel capacity

3,000 l

(793 gal)

Description

This M62P is built in infusion, one of the key points in the construction method is in the area below the waterline.

This is not built in sandwich but completely in solid skin up to the topside of the hull. This solution guarantees better peace of mind to the owner both during navigation and when the boat will be stored ashore for long period.

The rest of the boat is built in sandwich using vinylester resins and fiberglass. The hull structures are reinforced with carbon fibers and the flybridge and T-Top are made in carbon to reduce the weight at the top. The M62P is a semi-displacement hull and has a CE certification – Category A.

The main deck and the flybridge are covered in teak. As external finishing the yard can offer two different options: white gelcoat finishing for hull and deck or boat completely painted according to client’s preferences. The hydraulic platform at the stern allows the owner and guests to have direct access to the sea, manage the hauling and launching of the tender and move it into the tender garage.

On the main deck the “C” shaped galley is located on starboard side and a living area with sofa and a coffee table on port side. The galley overlooks the internal wheelhouse and next to it the staircase to access the lower deck where the master and guest cabins are located with their en-suite heads.

The aft main deck area includes a large dining table, a relaxation zone furnished and refined with everything you need to feel just like at home, without any sacrifices. The elegant carbon staircase leads to the flybridge where a private sun lounge equipped with sunbeds, fridge and cooking area where you can find your own place in the sun.

Catalogs

M62P

28 Pages

Related Searches

- Luxury yacht

- Luxury motor-yacht

- Cruising motor yacht

- Flybridge yacht

- Flybridge motor yacht

- 4-cabin motor yacht

- Wheelhouse motor yacht

- IPS motor yacht

- Power catamaran motor yacht

- 2-cabin motor yacht

- Composite motor yacht

- Open motor yacht

- Open yacht

- Carbon fiber motor yacht

- 6-cabin motor yacht

- Semi-displacement hull motor yacht

- 4-berth motor yacht

- Soft-top motor yacht

- Outboard motor yacht

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.