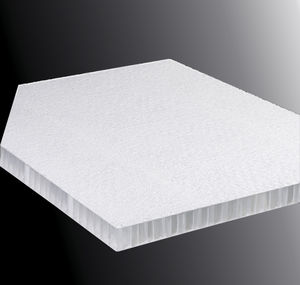

PP honeycomb core material NIDAPLAST 8DBflexible

Add to favorites

Compare this product

Characteristics

- Type

- PP honeycomb

- Properties

- flexible

Description

The nidaplast 8DB has been specially designed to facilitate the production of shaped parts.

Its 30x30 mm checkerboard cutout on one side of the core allows curved parts to be produced.

Nidaplast products are polypropylene honeycomb intended to serve as a core for structural sandwich panels.

Honeycomb panels for the production of curved parts

The nidaplast products are made of polypropylene honeycomb intended to serve as a core for sandwich panels.

Large structural sandwich panels: 2500 x 1220 mm

Different thicknesses: from 10 to 28 mm (other thicknesses on request)

Cell size: 8 mm

Indicative surface mass for a 20 mm panel: 1.5 kg / m2

The honeycomb has a density of 65 kg / m3 which allows good resistance to impact and compression.

The compressive strength of Nidaplast 8DB is 1.2 Mpa (120 Tons / m2)

The polyester nonwoven (45 g / m2) present on the nidaplast honeycomb cores offers an ideal surface for bonding or impregnation with thermosetting resins (polyester, epoxy, etc.).

The thermo-welding of this nonwoven on the honeycomb structure ensures it a perfect grip.

The plastic film (50 μm) placed under the nonwoven makes the cells waterproof and limits the consumption of resin or glue.

The honeycomb is made of polypropylene, a durable and 100% recyclable material.

The honeycomb structure composed of 95% vacuum uses little material while ensuring high mechanical properties.

Product sold exclusively to professionals and from a certain order threshold.

Structural sandwich panels are available from our resellers

The nidaplast 8DB honeycomb cores are manufactured at our industrial site in France.

Catalogs

No catalogs are available for this product.

See all of Nidaplast‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.