Furniture manufacture honeycomb panel NIDASKINpolypropylenepolyester

Add to favorites

Compare this product

Characteristics

- Applications

- for furniture manufacture

- Material

- polypropylene, polyester

Description

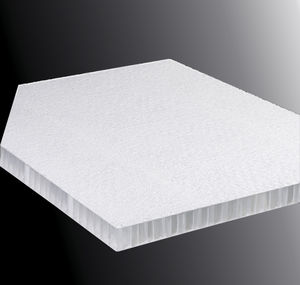

Nidaskin sandwich panels consist of a polypropylene honeycomb core, 8mm mesh. They have a previously glued skin on each side. Thermoplastic honeycombs are the result of the combination of plastic and honeycomb structures.

Different types of skin are available for immediate use of the sandwich panel: polyester, non-slip, etc.

Honeycomb core material:

Nidaskin panels are made of air cores. They are therefore very light and considerably lighten the structures.

Dimensions of a panel: 1220 x 2440 mm

Rot-proof core material :

Polypropylene honeycombs are insensitive to water and most solvents. The core material does not rot or generate swelling of the sandwich panel if the skin is punctured.

The different types of skin offered by Nidaplast for sandwich panels:

Nidaskin finished panels offer a wide range of possibilities for applications in many areas: interior design, layout, partitioning, doors, furniture, etc.

Sandwich panel with polyester skin:

Core material: polypropylene honeycombs (65 kg / m3)

Cell size: 8 mm

Type of skins: white polyester reinforced with fiberglass (RAL 9016) glued on both sides with polyurethane glue.

Skin thickness: 1.5 mm. Peelable film for skin protection.

Compressive strength (for a 20 mm thick panel): 1.2 MPa

Shear strength (for a 20 mm thick panel): 0.4 MPa

Available thicknesses:

10 mm (density 4.8 kg / m2)

15 mm (density 5.2 kg / m2)

20 mm (density 5.5 kg / m2)

25 mm (density 5.9 kg / m2)

30 mm (density 6.2 kg / m2)

Sandwich panel with non-slip polyester skin:

Core material: polypropylene honeycombs (65 kg / m3)

Cell size: 8 mm

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.