- Products

- Inboard engine

- Outboard Group Motors

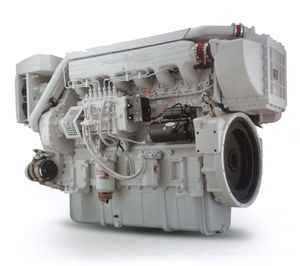

Inboard marine engine PD M seriesboating

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- inboard

- Market

- boating

Description

Spiral intake pipe

The intake pipe circulates the combustion gases in a spiral pattern around the cylinder axis. The resulting mixture of air and atomized fuel injection makes optimal. The upper end of the cylinder form a combustion chamber in a bar shape further reduces emissions.

The upper end of the cylinder form a combustion chamber in a bar shape further reduces emissions.

Low inertia vent type injection needle.

The fuel spray is mixed with air slowing the cycle to promote efficient burning.

Plate type electric heater.

The gas cylinders are preheated before entering the cylinder for improved performance in low-temperature startup.

Integrated exhaust manifold and heat exchanger design

The integrated design of the exhaust manifold heat exchanger and exhaust manifold placed in a cavity surrounded by water. Outside water circulation reduces the temperature of the exhaust gas. The best cooling effect and the noise is less. The heat exchanger tank replaces a radiator and cooling fan to the more compact structure.

Catalogs

No catalogs are available for this product.

See all of Outboard Group Motors‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.