- Maritime equipment

- Navigation, Communications, Electronics

- Loading software

- Praxis Automation Technology

Loading software VCMSfor shipsfor liquid cargoes

Add to favorites

Compare this product

Characteristics

- Function

- loading

- Applications

- for ships

- Other characteristics

- for liquid cargoes

Description

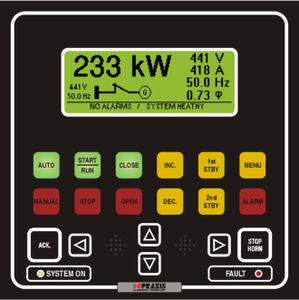

The Mega-Guard Valve Control and Monitoring System (VCMS) provides remote valve and pump control via Operator Workstations to assist the crew in cargo handling, ballasting, anti heeling and fuel oil transfer operations. The Mega-Guard VCMS is mainly applied on product tankers, chemical tankers, supply vessels, container vessels, bulk carriers and Ro-Ro ferries.

The Mega-Guard VCMS consists of Operator Workstations with dedicated mimic diagrams (cargo handling, ballast control, anti heeling and fuel oil transfer) connected to Distributed Processing Units which are built-up with Control Processors, I/O Modules and Serial link I/O Modules. Sensors (level, temperature, pressure, etc.), valves and pumps are directly connected to the I/O Modules and Serial link I/O Modules. The Operator Workstations and the Distributed Processing Units are interconnected via a redundant Ethernet link. The whole system is operating on 19-32VDC supply voltage and moving parts such as hard disk drives are not applied; solid state disks are used instead. The Mega-Guard VCMS is the most reliable system with a MTBF which outperfoms our competitors because of these facts.

The software of Mega-Guard VCMS is standardized as control functions are written with IEC61131-3 compliant building blocks. This guarantees proper and standardized documentation of each control function in order to allow for easy operation and maintenance by ship's crew as well.

Catalogs

DP

12 Pages

Related Searches

- Professional video camera

- Video surveillance video camera

- Ship video camera

- Fixed video camera

- Ship software

- Compact video camera

- Video camera with zoom

- Autopilot

- Color video camera

- Standard autopilot

- Ship monitoring system

- Ship autopilot

- Integrated bridge system

- Dynamic positioning system (DPS)

- Ship dynamic positioning system (DPS)

- Ship integrated bridge system

- Loading software

- Fuel monitoring system

- Ship power management system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.