- Sailing

- Sailing Equipment and Gear

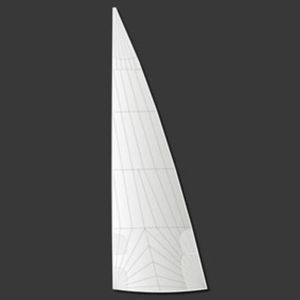

- Mainsail

- Quantum Sails

Mainsail TR 1600for racing sailboatstri-radial cutpolyester

Add to favorites

Compare this product

Characteristics

- Type

- mainsail

- Applications

- for racing sailboats

- Cut

- tri-radial cut

- Material

- polyester

Description

Series 1600 utilizes tri-radial construction with pre-made polyester composite materials. Large, unwoven polyester fibers (scrim) are sandwiched between exterior layers of woven polyester (taffeta). A polyester film provides off threadline (bias) stability.

BOAT SIZE

40' and under

MATERIAL

Polyester composites with taffeta exterior skins

Tri-radial sails utilize panels of pre-made materials radiating from the three corners of the sail. The long, or “warp” fibers of the material are oriented to align with the primary load paths. Better alignment results in lower stretch improving shape holding. Tri-radials provide a performance upgrade for those who are looking for more than what a classic woven polyester sail can provide

Designed for Maximum Control

When it comes to boat handling and speed, it’s sail shape that makes the difference. To achieve the ideal shape, Quantum’s sail designers use proprietary computational tools, part of the iQ Technology® suite, to create custom shaping, tailored on a sail-by-sail basis to expected usage and boat-specific constraints such as mast bend, displacement, and righting moment

The Right Materials

There is a broad spectrum of material options ranging from simple woven materials, to custom composites and they are available from a variety of suppliers. In general, there are three categories:

Woven Radial: Woven polyester specially designed with strength in the long (warp) direction so they can be used in tri-radial panel configuration. Compared to cross-cut woven polyester, this material offers 10 to 20% less stretch due to the material and the efficiency of the panel layout. Works well on boats up to 30’.

Catalogs

No catalogs are available for this product.

See all of Quantum Sails‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.