- Equipment

- Water, Electricity

- Boat cable

- Sea Cables

Electric cable HO7RN – Fmarine

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Application domain

- marine

Description

Used as signal and communication cables in radio, radar and information systems of marine vehicles. It’s twisted pairs enables proper transmission of high frequency signals, while it’s overall screen minimizes environmental electromagnetic interference.

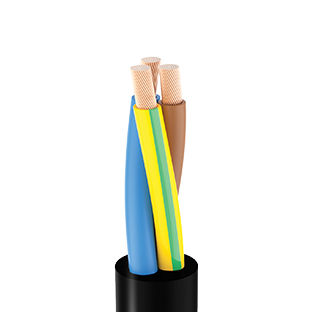

Cable Structure

CONDUCTOR : Electrolytic, stranded, annealed copper wire IEC 60228 Class 5 (Class 2 and / or tinned on request)

INSULATION : Cross linked polyethylene compound (XLPE).

SEPARATOR : A suitable tape may be applied over the conductor

CORE IDENTIFICATION: Acc. to HD 308.

INNER SHEATH : EM2 or EM3 type elastomer compound (if outer sheath thickness is greater than 2.4 mm)

OUTER SHEATH : Halogen-free, flame retardant, polyolefin based compound (SHF1).

COLOR : Black (other colors on request)

Standards & Main Characteristics

CONDUCTOR : EN 50525-2-21, DIN VDE 0282-4, BS 6500 BS 7919, IEC 60245-4

GENERAL REQUIREMENTS : EN 50525-1, HD 22.1, DN VDE 0282-1, IEC 60245-1

GUIDE TO USE : HD 516, DIN VDE 0298-300

ELECTRICAL TESTS : EN 50395, IEC 60245-2

NON – ELECTRICAL TESTS : EN 50396, IEC 60245-2

CONDUCTOR RESISTANCE : EN / IEC 60228, HD 383, DIN VDE 0295, BS 6360

WORKING TEMPERATURE IN MOBILE USE : -25ºC / +60ºC

IN FIXED USE : -35ºC / +85ºC CONDUCTOR SHORT – CIRCUIT TEMP. : Max. 200ºC

TEMP. ON CABLE SURFACE : Max. +50ºC

MIN. INSTALLATION TEMP. : -25ºC

MIN. BENDING RADIUS : HD 516 Table 6.C

MAX. TENSILE LOAD : 15 N / mm2

CURRENT CARRYING CAPACITIES : HD 516 Table 7.C VDE 0298-4

FLAME RETARDANT : EMEC 60332-1-2, DIN VDE 0482-332-1-2

OIL RESISTANT : HD/EMEC 60811-2-1, DIN VDE 0473-811-2-1

Catalogs

No catalogs are available for this product.

See all of Sea Cables‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.