- Ship and boat building

- Materials and paints

- Epoxy resin

- SKF Solution Factory - Marine Services

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy resin Epocastmachine chocking

Add to favorites

Compare this product

Characteristics

- Type

- epoxy

- Applications

- machine chocking

Description

Epocast is a two-component chocking compound enriched with high-grade fillers.

Advantages:

Can fill most irregularities between foundation and machine

Reduces noise and vibration

We work with two types of Epocast, each with their own specific advantages.

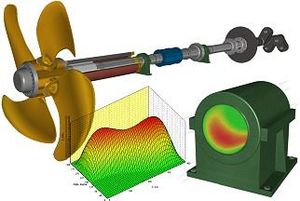

The basic is Epocast 36®, which is an epoxy resin chock for mounting main and auxiliary engines, gear boxes, steering gears, thrust bearings, stern tubes, etc. Its main benefits are the ability to fill any reasonable irregularity in the chocking interface and to reduce noise and vibration.

Epocast 36-P is a trowelable two-component epoxy paste which was specifically developed for installation of LNG/LPG tanks, chemical tanks and containment systems. Its main advantage over the standard Epocast is can be used in applications where a freely floating resin is not practical.

In addition to the product we also offer the service of executing the chocking making use of Epocast. Installation of Epocast is only to be done by SKF Solution Factory - Marine Services, or a SKF Solution Factory - Marine Services authorised company.

Catalogs

No catalogs are available for this product.

See all of SKF Solution Factory - Marine Services‘s catalogsOther SKF Solution Factory - Marine Services products

Marine & Offshore Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.