- Ship and boat building

- Materials and paints

- Soundproofing foam

- Soundown Corporation

- Products

- Catalogs

- News & Trends

- Exhibitions

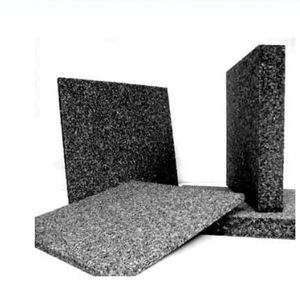

Soundproofing foam VINYL

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- soundproofing

Description

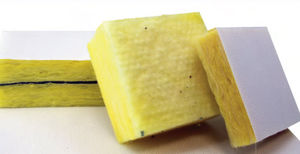

SOUNDOWN S Vinyl/Foam composite insulation is an effective treatment for airborne noise that radiates from engines, and other machinery. The standard composite consists of a layer of mass loaded vinyl sandwiched between two layers of polyether fire retardant foam covered by a thin attractive vapor barrier facing.The composite is designed and manufactured specifically for attenuation of sounds from machines such as engines, generators, pumps, and other marine equipment which may have significant base and mid-range frequency components. Our construction centers the acoustic vinyl between equal hicknesses of foam, front and back.This configuration optimizes the mid

and bass frequency sound isolation in comparison to other materials with only a thin foam layer on the bac kside; solely optimized for “tinier” high-frequency noise. Vinyl/Foam composite insulation from SOUNDOWNis available in a number of formats for optimal sound attenuation within the available space.

Soundown is able to tune this attenuation by utilizing barrier material of 0.5 lb.,1 lb., 1.5 lbs., or 2 lbs. per square foot in our composites. In areas where hatch and bulkhead clearances do not allow the use of thicker composites we may substitute heavier barrier material so that performance is not ompromised. Likewise, in weight critical applications, lighter barriers may be used in thicker composites.

Catalogs

Polyimide Cut Sheet2009

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.