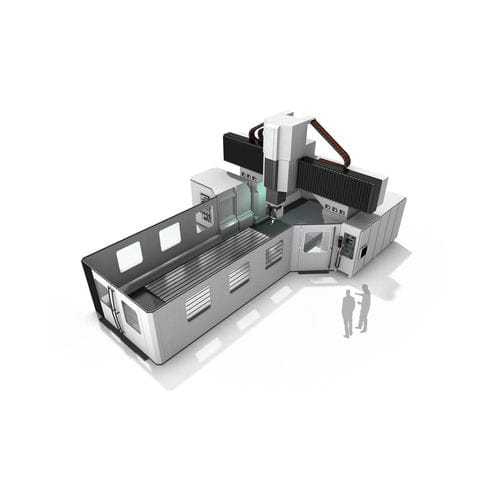

For machine manfacturers and toolmakers, flexibility, cost effectiveness and precision play a very important role, especially when machining large components. These three requirements are what led to the development of the TFS portal machining center with its fixed cross-rail. Customers use the modular principle to select the table configuration, control systems and milling units appropriate to their individual tasks. The flexible D40 ram-type milling unit with its integral C-axis, provides a stable platform for our wide range of milling heads, from a conventional vertical spindle through fixed angle heads and on to 3+2 axis and full 5-axis contouring.The large number of well proven, automatically exchangeable milling heads increases the range of suitable applications. The TFS range of attachments also includes automatic spindle changing as well as tool and component measurement.Key benefits:- D40 ram-type milling unit provides stability and flexibility- Large number of automatically exchangeable milling heads- Various table designs (long, double, rotary, or with pallet changing system)- Numerous peripheral attachments- Automatic tool changer- Automatic milling head and spindle changer- Integrated tool and component measurement solutions- Heidenhain or Siemens control unit options