- Ship and boat building

- Production machines and tools

- Stierli Bieger AG

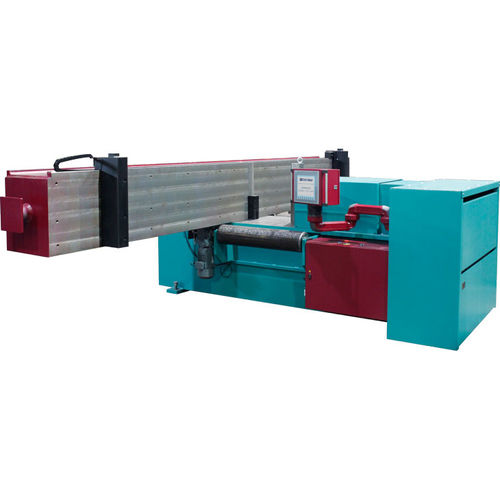

Shipyard bending press 4400 CNChydraulicCNC

Add to favorites

Compare this product

Characteristics

- Application domain

- for shipyards

- Operation

- hydraulic

- Control type

- CNC

Description

The “4400 CC” hydraulic horizontal press ticks every box as far as flexibility and the range of performance of the control system are concerned. The CNC control is used primarily for pre-tensioning steel beams. The machine meets the highest requirements of large steel construction companies, which often camber beams, and of steel service centres, which offer bending of steel beams (cambering, pre-tensioning) as additional services. The robust, heavy design of this bending press guarantees precise bending results.

The special feature of this horizontal bending press lies in the use of a laser-operated control system, which provides the best possible support for the process of cambering steel beams. The operator can enter the height of the arch numerically. The hydraulic horizontal press then controls the cylinder stroke and the beam feed of the powered roller conveyor in automatic mode.

Main application:

Cambering (pre-tensioning, cambering) of steel beams

Other applications:

Straightening and bending steel beams in both axes (vertical and horizontal)

Straightening of steel profiles (L profiles, T profiles, I profiles, Z profiles, U profiles, rail profiles, special profiles)

Straightening of welded parts and welded structures

Straightening of steel plates and flame-cut parts

Heavy form bending work (work with heavy v-blocks or dies)

Bending and straightening of very large pipes

The powerful CNC with laser control is the result of STIERLI-BIEGER’s expertise in the construction of modern, high-quality bending and straightening machines, acquired over many years.

Catalogs

Main brochure

36 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.