Shipyard bending machine 820 NC - SEhydraulicprofile

Add to favorites

Compare this product

Characteristics

- Application domain

- for shipyards

- Operation

- hydraulic

- Product handled

- profile

Description

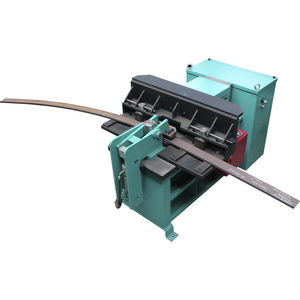

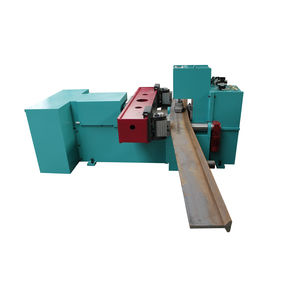

The “820 NC - SE” ship’s frame bending machine is designed for bending profiles for ship’s frames. As well as HP ship’s frames (HP profiles, Holland profiles or bulb flats), other profiles such as L and T profiles can be bent. The ship’s frames can be bent individually or in pairs. The direction of machining (S bends) can be switched without changing the bending tools. The bending process can be carried out quickly and precisely. The operator is assisted by the straightforward NC+ control system with fine stroke adjustment. Up to 200 bending and straightening programs can be created, in which the movements of powered support rollers can be programmed. In automatic mode, ship’s profiles can therefore be processed economically.

The universal ship’s frame bending machine can be used for the following bending and straightening work:

Bending ship’s frames (HP profile, bulb flats, Holland profile)

single / double

Bending T-profile, L-profile

Edge bending of flat steel

Bending of special profiles

By resetting the tools, the machine can also be operated as a universal straightening and bending machine:

Bending pipes up to 3”

Bending flat steel with v-blocks

Carrying out various types of straightening work

Straightening of welded parts and welded structures

Straightening of steel plates and flame-cut parts

Heavy form bending work (work with heavy v-blocks or dies)

The robust and heavy design of this ship’s frame bending machine guarantees precise bending results. The open design enables optimal part handling and loading of the machine using a factory crane or powered roller conveyor.

Catalogs

No catalogs are available for this product.

See all of Stierli Bieger AG‘s catalogsOther Stierli Bieger AG products

Bending machines for ship’s profiles

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.