- Maritime equipment

- Navigation, Communications, Electronics

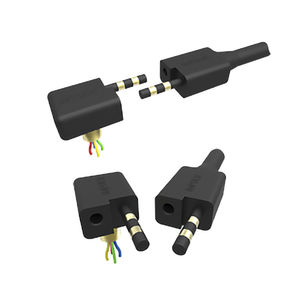

- Underwater connector

- Teledyne D.G.O'Brien

Electric connector 100 Mil-C-24231underwater4 contacts3 contacts

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Application domain

- underwater

- Contact number

- 4 contacts, 3 contacts, 40 contacts, 28 contacts, 24 contacts, 8 contacts, 13 contacts, 14 contacts, 5 contacts, 6 contacts, 12 contacts, 10 contacts, 22 contacts, 19 contacts, 16 contacts, 25 contacts, 7 contacts, 18 contacts, 9 contacts, 21 contacts

Description

The Teledyne DGO 100 Series connectors are designed, manufactured and tested in accordance with the stringent requirements of Mil-C-24231 and used primarily in Navy dry mate submersible interconnect applications.

Polyurethane over-molding is the most common method for termination and bonding a cable and connector. Teledyne DGO is a Navy ProMold Certified supplier and offers a variety of PU molding shapes and configurations. An NCC bond enhancement coating is standard. NCC coating is a non-cathodic coating developed by the US Navy and governed by Navy Molding Manual specifications.

Optional advanced coatings are available for application to the metal plug shell surfaces to delay the cathodic bond delamination including DGO-1, a proprietary factory applied advanced performance primer.

Alternately, a GRE (Glass Reinforced Epoxy) over-coated version is available for applications where cathodic delamination is considered high risk.

100 Series receptacles are supplied with 15 foot pigtails for direct installation. The receptacle inserts are molded with high impact epoxy (chockfast) with a nickel copper body.

Key Features:

100 Series Plug connectors are supplied as both molded cable assemblies and in kit form and feature a polyurethane molded insulator with NiCu Shells.

Available in multiple shell insert arrangement configurations from 3-40 contacts, in mated pairs of straight and right angle plugs and receptacles.

Benefits:

The 100 Series Receptacle Connector contains integral glass-to-metal seals for proven pressure protection of equipment with a standard pressure rating of 2,000 psig.

Catalogs

No catalogs are available for this product.

See all of Teledyne D.G.O'Brien‘s catalogsRelated Searches

- Underwater connector

- ROV connector

- Bulkhead connector

- 4 contacts connector

- 8 contacts connector

- 2 contacts connector

- Wet-mate connector

- 3 contacts connector

- 6 contacts connector

- 5 contacts connector

- 12 contacts connector

- 10 contacts connector

- 16 contacts connector

- Dummy connector

- Inline connector

- 7 contacts connector

- 1 contact connector

- Penetrator

- Underwater penetrator

- Electric penetrator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.