Flexible mechanical coupling RBD for boatfor shipsfor diesel engines

Add to favorites

Compare this product

Characteristics

- Application domain

- for boat, for ships

- Applications

- for diesel engines

Description

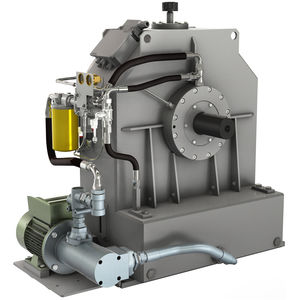

The RBD drives are designed for use with industrial engines in stationary applications such as generators, pumps and compressor sets. Mobile applications include fork lift trucks and earth moving equipment.

RBD drives have many advantages:

ease of assembly, weight and size, small axial profile and competitive price. Drives are also supplied with standard SAE flanges for ease of installation.

Now they are also available in SRBD version; it means RBDs complete with SAE or DIN 5480 finished hubs and selected SAE flanges in order to facilitate and speedy the Customer selection at competitive price.

Atex certification is available too.

CONFIGURATION

Couplings can be provided:

with or without hub

with spline or keyway

with conical locking coupling

with housing for hydrostatic drives

TECHNICAL CONSTRUCTION

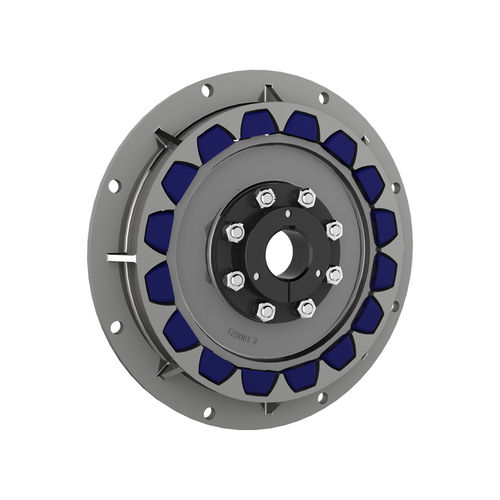

The drive principle makes use of internal and external teeth; the only difference being that the external teeth are blocks of special rubber molded compound.

The external ring, in aluminum, has a profile corresponding to the rubber molded compound and can be directly mounted on the output flange of the prime mover.

By this method it is also possible to absorb small angular and radial misalignments.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Motor reduction gearbox

- Boat reduction gearbox

- Transfluid mechanical coupling

- Transmission reduction gearbox

- Transfluid ship mechanical coupling

- Transfluid boat mechanical coupling

- Propulsion system

- Flexible mechanical coupling

- Ship propulsion system

- Hybrid propulsion system

- Work boat reduction gearbox

- Boat propulsion system

- Electric propulsion system

- Ferry reduction gearbox

- Shaft drive propulsion system

- Ship drive unit

- Transfluid diesel engine mechanical coupling

- Mechanical drive unit

- Transfluid hydrodynamic mechanical coupling

- Yacht propulsion system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.