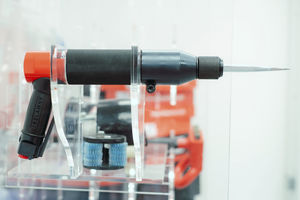

Needle scaler 196.2107for shipyards

Add to favorites

Compare this product

Characteristics

- Options

- needle, for shipyards

Description

ATEX certified quality design and low vibration Trelawny’s VL (Vibro-Lo ™) Needle scalers have long been the market leading tools for descaling, offering unparalleled reductions in harmful vibration, containment of hazardous dust and drop protection. In our aim to produce the highest performing, safest tools for use in hazardous environments Trelawny offer our ATEX certified versions of the full VL range of needle scalers. The VL Ex series is based around our VL303 & VL203 pistol grip scalers and the VL223 in line scaler. Trelawny’s VL Ex series is the solution for corrosion management in high risk surroundings such as natural-gas installations, oil and LNG tankers, gas works, oil drilling platforms, refineries, petrochemical plants and shipyards.

Trelawny’s VL Ex series is the solution for corrosion management in high risk surroundings such as natural gas installations, oil and LNG tankers, gas works, oil drilling platforms, refineries, petrochemical plants and shipyards

Removal of coatings, corrosion and other accumulated materials

Beryllium Copper needles fitted as standard – Beryllium copper provides high strength with non-sparking and non-magnetic properties

TVS® Dust shroud options available – Ensures that operators are protected from hazardous dust present in the coating and corrosion they are removing, dust from Beryllium copper is hazardous and we strongly recommend that the VL Ex series is used in conjunction with the KAV Ex range of dust collectors

Fall arrestors – A simple drop protection solution is available on all VL Ex tools, eliminating the risks of dropping the tool which could cause injury, equipment damage and downtime

Vibro-Lo™ vibration reduction

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.