- Harbors and port terminals

- Port equipment

- Harbor fender

- Trelleborg Marine and Infrastructure

- Products

- Catalogs

- News & Trends

- Exhibitions

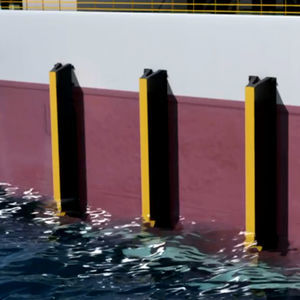

Harbor fender SISOfor terminalspierpanel

Add to favorites

Compare this product

Characteristics

- Application domain

- for harbor, for terminals

- Applications

- pier

- Configuration

- panel

- Other characteristics

- slip

Description

Utilizing removable sliding panels, the patented ‘Slide In, Slide Out’ (SISO) fender system has been designed to significantly reduce the time and effort taken to complete a fender wear pad change-out.

Unlike traditional fender frame systems where ultra-high-molecular-weight polyethylene (UHMWPE) wear pads are fixed directly to a fixed frontal frame via a bolt fastening arrangement, the UHMWPE wear pads are bolted onto two stainless steel removable panels. These panels are then inserted into a guide rail on the front face of the fixed frontal frame. The sliding panels can then be easily lifted out of the frontal frame and replacements reinserted within two hours – reducing downtime on the berth and keeping operations running punctually.

The original panels can then be transported onshore for maintenance and have their wear pads replaced, ready to be used as spares for the next fender wear pad change-out operation. The system also reduces the safety risks and downtime associated with completing a pad replacement work from either a workboat or when using a maintenance scaffold system.

Features

Removable sliding panels

High performance

Simple and quick maintenance

Applications

⮚ General cargo berths

⮚ Bulk terminals

⮚ Oil and LNG facilities

⮚ Container berths

⮚ RoRo and cruise terminals

Fender Quality Framework

The Fender Quality Framework details the latest research into rubber fenders to provide a central resource for smarter fender selection. You will find an overview of our deep research library, with links to more in-depth resources such as relevant reports, webinars and specification clauses.

Learn more

Catalogs

Fender Systems

86 Pages

Other Trelleborg Marine and Infrastructure products

Fixed Fenders

Related Searches

- Trelleborg Marine Systems fender

- Buoy

- Dock fender

- Boat fender

- Trelleborg Marine Systems harbor fender

- Plastic buoy

- Circular fender

- Black fender

- Trelleborg Marine Systems pier fender

- Inflatable fender

- Mooring buoy

- HDPE buoy

- Terminal buoy

- Ships fender

- Blue fender

- Trelleborg Marine Systems mooring bollard

- Foam buoy

- Gray fender

- Pneumatic fender

- Terminal fender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.