- Harbors and port terminals

- Port equipment

- Harbor fender

- Trelleborg Marine and Infrastructure

- Products

- Catalogs

- News & Trends

- Exhibitions

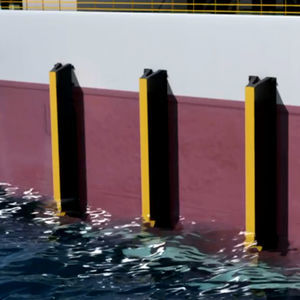

Harbor fender Rubbylene®pierpileledge

Add to favorites

Compare this product

Characteristics

- Application domain

- for harbor

- Applications

- pier, pile

- Configuration

- ledge

- Material

- composite

Description

Composite fenders, also called Rubbylene®, are composites of rubber which provides resilience and UHMWPE with low friction and wear resistant properties. The two materials are bonded with a special vulcanising method which is stronger and more reliable than a mechanical joint.

Composite fenders are used where the simplicity of extrusions are required but with lower shear forces.*

Features

Resilient rubber body

Low-friction UHMW-PE face

Strong molecular bond

Easily drilled and cut

Applications

⮚ Jetties and wharves for small craft

⮚ Mooring pontoons

⮚ Pile guides on floating structures

Fender Quality Framework

The Fender Quality Framework details the latest research into rubber fenders to provide a central resource for smarter fender selection. You will find an overview of our deep research library, with links to more in-depth resources such as relevant reports, webinars and specification clauses.

Learn more

Fender Online Tools

Try our new fender online tool, with enhanced features, including specification generators for fenders and bollards and a fender system selector for ship-to-ship applications. Developed in accordance with PIANC guidelines and British Standards, the tool simplifies fender selection, reducing hours of work to a few clicks.

Open tool

Multipurpose and Tug Fenders Brochure

Find out more about Trelleborg’s wide ranging Multi-Purpose and Tug Fenders customized to meet your requirements.

Download PDF

Marine Fender Performance Verification

In this new User Guide, Trelleborg suggests moving towards independent testing as a means of guaranteeing fender performance.

⮚ Inland waterways

Catalogs

Multipurpose and Tug Fenders

44 Pages

Surface Buoyancy

24 Pages

Other Trelleborg Marine and Infrastructure products

Fixed Fenders

Related Searches

- Trelleborg Marine Systems fender

- Buoy

- Dock fender

- Boat fender

- Trelleborg Marine Systems harbor fender

- Plastic buoy

- Circular fender

- Black fender

- Trelleborg Marine Systems pier fender

- Inflatable fender

- Mooring buoy

- HDPE buoy

- Terminal buoy

- Ships fender

- Blue fender

- Trelleborg Marine Systems mooring bollard

- Foam buoy

- Gray fender

- Pneumatic fender

- Terminal fender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.