- Ship and boat building

- Materials and paints

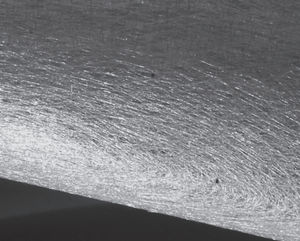

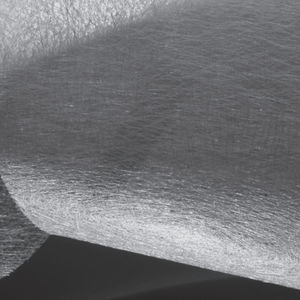

- Fiberglass composite fabric

- Vetrotex - OCV Reinforcements

Fiberglass composite fabric SE2307roving

Add to favorites

Compare this product

Characteristics

- Fiber

- fiberglass

- Type

- roving

Description

SERVICE LIFE PERFORMANCE

SE2307 single-end roving is designed to provide extended service life (20+ years) and hydro-thermo stability for high performance filament would epoxy pipe under pressurized conditions.

Versatility

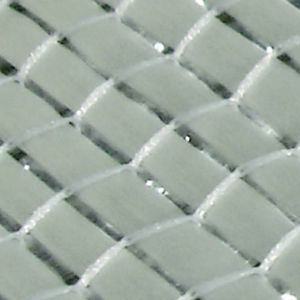

Designed for use in filament winding, compatible with a variety of curing systems—giving flexibility with one glass input and higher glass loading.

Flexibility to meet pipe user requirements for high mechanical properties, durability, corrosion resistance, and low weight.

Excellent Processing

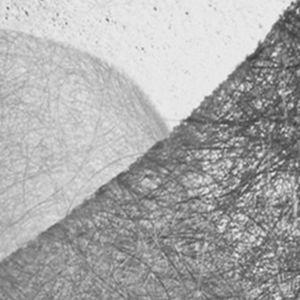

Fast wetting and smooth run-out combined with low fuzz properties, result in smoother parts and less downtime for clean-up, enabling higher efficiencies and lower manufacturing costs.

Enhanced Service Life

Excellent hydro-thermo stability and strength retention under pressurized conditions, leading to long service life for installed pipe.

Outstanding Mechanical Properties

Excellent properties in multiple curing systems; improved axial tensile strength, inter-laminate shear strength and burst stress for high performance filament wound epoxy pipe applications.

APPLICATIONS

SE2307 single-end roving is specifically designed to match the unique needs of the high performance epoxy pipe market in a variety of applications: power & energy (refineries, power plants, off-shore platforms), industrial (petrochemical), and transportation (marine).

Catalogs

No catalogs are available for this product.

See all of Vetrotex - OCV Reinforcements‘s catalogsOther Vetrotex - OCV Reinforcements products

COMPOSITE PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.