- Products

- Vetrotex - OCV Reinforcements

Milled fiber compositechopped

Add to favorites

Compare this product

Characteristics

- Material

- composite

- Technical characteristics

- milled, chopped

Description

PERFORMANCE WITH VERSATILITY

Owens Corning® Milled Fibers are designed to enhance mechanical properties, increase stiffness, improve dimensional stability, and minimize distortion under elevated temperatures.

Excellent Dispersion & Impregnation

• Pre-dispersed nature promotes excellent dispersion in the matrix.

• Short-fiber thermoplastic compounds will show improved melt flow characteristics with shorter input fiber lengths.

Impressive Aesthetics

• Fiber length and excellent distribution qualities provide a homogeneous, highly pigmentable surface with limited fiber prints and good color.

Enhanced Part Strength

• Glass reinforced parts exhibit improved mechanical properties, modulus and dimensional stability.

Applications

Milled Fibers are designed to be used in a wide variety of applications in automotive, electrical, consumer, construction, marine, and aerospace industries, including high-flow glass reinforced thermoplastic compounds, PTFE gaskets and seals, repair putties, friction and clutch materials, and specialty paints.

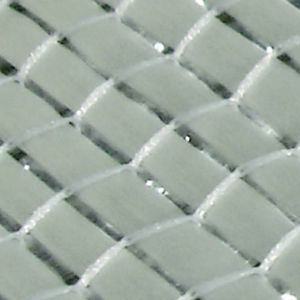

Product Appearance

Powder

Relatively free-flowing with a high bulk density for use in formulations requiring very uniform dispersion and short fibers with median fiber lengths typically in the range of 40 - 110 microns.

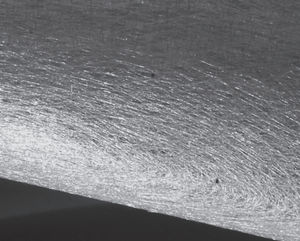

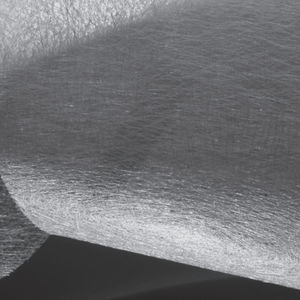

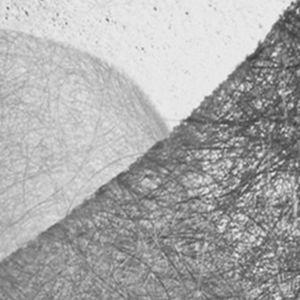

Floccular

Small nodules of glass filaments for use in formulations requiring increased bulk or longer filaments with typical median fiber lengths in the range of 180-200 microns.

Catalogs

No catalogs are available for this product.

See all of Vetrotex - OCV Reinforcements‘s catalogsOther Vetrotex - OCV Reinforcements products

COMPOSITE PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.