- Ship and boat building

- Materials and paints

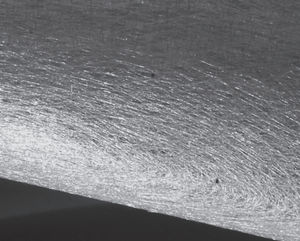

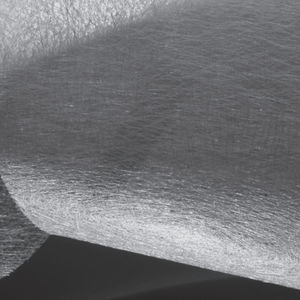

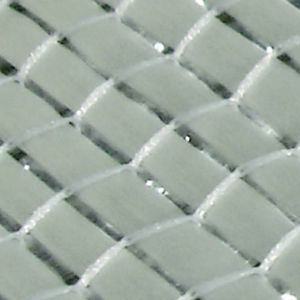

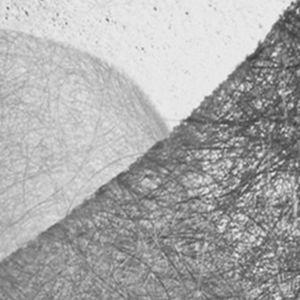

- Fiberglass composite fabric

- Vetrotex - OCV Reinforcements

Fiberglass composite fabric PulStrand® 4100roving

Add to favorites

Compare this product

Characteristics

- Fiber

- fiberglass

- Type

- roving

Description

MAXIMIZE PERFORMANCE, MINIMIZE COST

PulStrand® 4100 is specifically designed for fast wet-out, good processing, high glass loading and excellent laminate properties, to maximize customers’ processing and minimize their processing costs in pultrusion applications.

Outstanding Mechanical Properties

Excellent shear and flexural properties in major resin systems, provide maximum part strength and long part service life.

Reduced Cost

Fast, uniform strand wet-out leads to higher glass loading, reducing resin demand; fast wet-out also increases production speed and productivity resulting in reduced manufacturing cost.

Multi-resin Compatibility

Excellent glass/resin bonding in polyester, vinyl ester, polyurethane, acrylic, and epoxy resins, providing the processor maximum flexibility with one input glass. This reduces cost with less inventory to carry and eliminates the need for costly downtime and labor to change input glass during job changes.

Suitable for LFTP PA compounding applications

Excellent Processing

Smooth run-out combined with low fuzz properties, result in smoother parts and less downtime for clean-up, enabling higher efficiencies and lower manufacturing costs.

Corrosion Resistant

Excellent corrosion resistance with Advantex® Glass compared to standard E-glass: providing longer service life in applications facing corrosion.

Catalogs

No catalogs are available for this product.

See all of Vetrotex - OCV Reinforcements‘s catalogsOther Vetrotex - OCV Reinforcements products

COMPOSITE PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.